Dear TI-

I am attaching my schematic for the IWR6843 radar for your review. My application is long-range people detection. This design uses two identical radar boards to enable a 180-degree field of view.

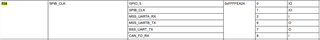

Do I need more I/O signals besides the two UARTs (Command and Log), the SOP2 pin for uploading the code, and the hardware reset? Ideally, I would like to coordinate the two radar boards to avoid interference. This is possible using the sensor start and stop commands. But I was hoping for an indication of when best to start and stop the individual radar (maybe the sync_in signal?) Mine is not a super time-critical application like cruise control, so the simple UART start/stop commands commands may be sufficient.

I appreciate any feedback/recommendations.

Mike Schell

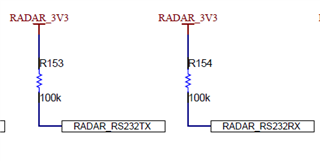

PS Do I need to add any pull-ups or pull-downs? The spec sheet indicates that most pins have this built into the chip.