Other Parts Discussed in Thread: TDC1000, , TUSS4470, MSP430FR6047

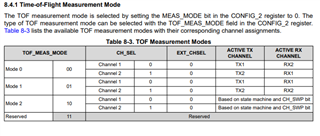

Hi,

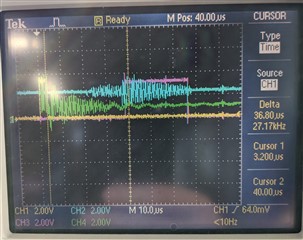

I'm using working on using the TDC1000-C2000EVM to evaluate the TDC1000. Our end goal is to use it for volume (from the top of the container down) and/or flow measurements for water. The transceiver we're using is a 1MHz transceiver - H2KMPYA1000600 from Unictron. Before doing our more targeted experimentation, I'm making sure that I can run and understand how the board and GUI work. I'm running into an issue where no matter how far away from a surface I place the ultrasonic transceiver, the TOF in the GUI is constantly reading ~38.5us. I can have the transceiver pointing at the ceiling or directly on my desk surface and the TOF does not change.

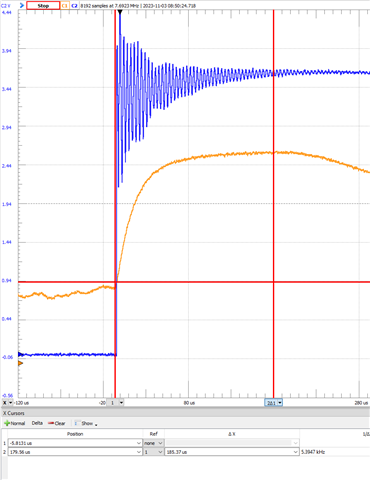

This is what I'm seeing on the scope. Yellow is START, pink is STOP, green is the signal at TX1, and blue is the COMPIN buffer.

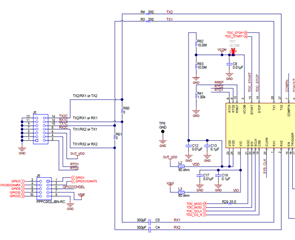

Here are the settings that are currently set.

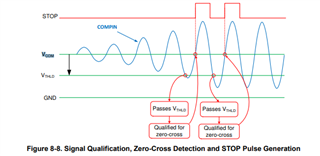

I've tried setting the autozero period to 512xT0 or 64us to avoid all ringing from the TX, but nothing is then ever received at any distance. I'm at a loss at to what needs to change to correctly see the TOF. Is there a setting that is wrong somewhere? Any guidance would be appreciated to help keep this design moving forward.

Thanks,

Tim