Other Parts Discussed in Thread: TCA9803, TCA9548A, TCA9544A, TCA9517

Hello E2E Sensor Team,

I am looking for your valuable feedback & insights on using the TMP1075 Digital Temperature Sensor for monitoring temperatures in an industrial setting.

Key aspects of our use case include:

Temperature Components: Monitoring temperatures of outer surface of bearing housing, motor casing, and piston cylinder in Industrial environment using a type of Ring Lug.

Temperature Range: Normal temperatures are below 90°C (for 99% of the lifetime) with occasional peaks up to 120°C, and a AMR of 150°C of the sensor shall always be respected.

System Configuration: We plan to use 4 x TMP1075 sensors, each connected via a 3-meter STP well grounded cable in a star configuration to a single I2C Master on the MCU, operating at/below 5kHz. We intend to use TCA9803 for driving these long cables.

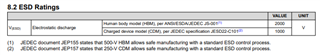

Protection Measures: Implementation of ESD314 for ESD, EFT, and surge protection on both power and data lines. We further plan to use RC filters on the I2C signal lines with 10kHz cutoff frequency.

Sensor Packing: We will create a custom Ring Lug encapsulation for the SOT package on small form factor PCB

Our queries to the Sensor Team:

- Is TMP1075 appropriate for our use case? Are we making any obvious mistake here?

- Any concerns with using ESD314 for device protection in this setup?

- Any feedback on the Star connection, use of TCA9803 in said setup?

- If we plan to use a I2C Multiplexer like TCA9548A, how will it impact the drive strength of the TCA9803 for the cables?

Your guidance will be instrumental in finalizing our design.

Thank you