Hello!

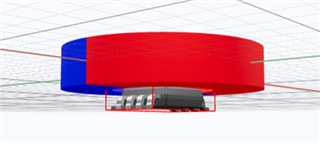

I am currently working on a precision angle sensing application involving the use of a 3-axis hall sensor in close proximity to a diametrically magnetized ring magnet (NdFeB). This is for a medical device which we aim to commercialize in early 2025.

In our application, the hall sensor is aligned coaxially to the magnet, and is calibrated using an external magnetometer which is placed in-plane, off-axis to the magnet.

I understand that sintered magnets have a magnetization direction tolerance resulting from individual grain magnetization. My uncertainty is whether the magnetic field near a magnet's surface will behave somewhat randomly due to grain structure behavior. If true, the theoretical relationship between magnetometer angle reading and hall sensor angle reading, which are in different places, could be inaccurate.

Do you have any insights into these concerns? We are trying to better understand magnetic field shape repeatability across a manufacturing lot, and whether near-field shape deviates from theoretical models due to grain magnetization. Ultimately, we'd like to find a combination of magnet selection and sensor design that results in the most accurate solution.

Best regards,

Lucas