Other Parts Discussed in Thread: DRV421,

Hello everyone,

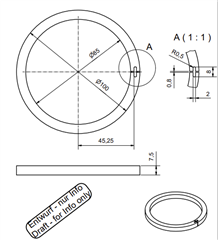

as I was asking about the suitable core for the DRV421 Evaluation Board, later we found one company who has succesfully produced this core for us. (see below).

The core is with Material Si - H085, magnet gain 660uT/A.

We are doing the DC current measurement with on this core now and there are unfortunately big ratio error between the primary current and the output voltage of the chip.

Here are some information about core windings and chip settings:

- Number of compensation coil windings: 2000; Coil resistance: 18.5Ohm, inductance: 700mH

- Rated primary current: 300A;

- Chip refernce voltage: 2.5V;

- Shunt resistance on the evaluation board, we have changed it into 1Ohm.

- Primary windings: 36

Now the problems come, we have always measured a bigger voltage increase or decrease referenced to 2.5V as it should be. We measure the voltage on the Shunt-Resistance from the primary, multiply it to the windungs to get information of primary current. We also measure the output voltage directly from the chip. In the output range of 0-5V, if the primary current is positive, then the output will increase upper 2.5V, this increasment should be proportional to the primary current, vice versa. The ratio between output voltage and primary current should follow this formula:

V_out = V_ref +/- 4*R_shunt*I_comp

Some data from our measurement below:

| -360A | 1.681V |

| -60A | 2.364V |

| -30A | 2.432V |

| 30A | 2.571V |

| 60A | 2.636V |

| 360A | 3.325V |

The measured error reachs near to 14% in this whole current range. The error doesn't vary a lot.

For example, the voltage with primary current at 360A should be:

V_out = 2.5V + 4*1Ohm*360A /2000 = 3.22V

However, we measure 3.325V, which means an big error.

We have also tried another core with our parameters and the output voltage is tendential being bigger than it should. It is difficult to find the reason, afterall, we have checked the compensation windings and different stuffs on the evaluation board and no chance to find the problem out.

A lot of Thanks if we are getting some ideas or helps!!

Best Regards

Yutong