Hello, I have two urgent questions about the use of LDC1612.

the first question:

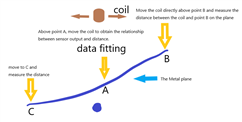

I use LDC1612 to measure the unevenness of the metal plane. There are two processes required here. One is to establish the relationship between sensor output and distance, and the other is to use LDC1612 to measure the height value. There are three questions here:

1. If the metal plane is inclined or the metal surface is uneven, use a coil to measure the inductance value and then convert it into a distance value. What does this distance value (inductance value) represent? Is it the average value of this inclined plane?

2. If the inclination of the metal plane used to establish the relationship between the sensor and the distance is inconsistent with the inclination of the measured plane, is the distance value of the measured plane reliable? In other words, if I establish the relationship between the sensor output value and the distance on a plane with an inclination of 5°, then I use this relationship to measure the planes with an inclination of 0° and 10°. Is the calculated distance accurate?

3. LDC1612 can get 3 kinds of output, including RAW, inductance value and frequency value. When I want to get the distance between the sensor output and the measured surface (used to measure the distance between other positions and the sensor coil), what type of output should I use? Can all output values be used?

the second question:

I use LDC1612 to measure a heated metal plane. Due to thermal radiation, the temperature of the coil plate of LDC1612 will change. What is the relationship between the output value of the sensor and the temperature of the coil plate? Is there any formula or related information?

Looking forward to your reply, thank you.