Other Parts Discussed in Thread: TMAG5170, , TMAG5170-CODE-EXAMPLE

Hi all,

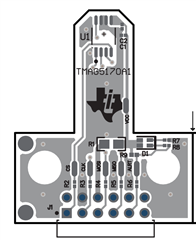

I'm currently trying to work with the Hall-Effect Sensor TMAG5170.TMAG5170UEVM

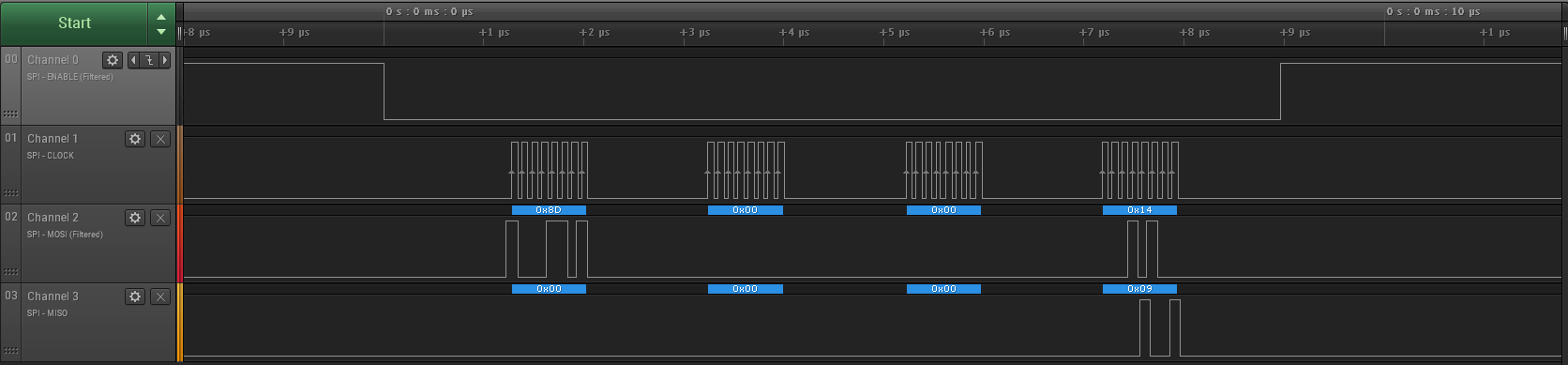

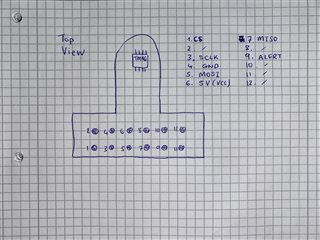

It uses SPI protocol to communicate with microcontrollers. I am using the Arduino IDE 2.3.0 and an Arduino Uno to try control the sensor and I am having much difficulty writing into the registers of the TMAG5170. It seems I am able to read the registers but I cannot write in them. I am quite certain my pins are all correctly connected, I have VCC=5V. I previously tried VCC=3.3V as well. I am unsure where to connect the ALARM pin, I assumed any GPIO pin can work, but in this project I don't even use the alarm feature. I am trying to use code given by TI Example Code by TI 1 . I have then tried to use code I found on GithubGithub Project 2 . It is essentially the same stuff as the TI example code. Using both examples (code from TI and from Github) I could read the registers but not write in them. I am really stumped, so here is my code so far and hopefully someone has time and expertise to see where I am going wrong:

#include "SPI.h"

#include "tmag5170.h"

#include "hal.h"

// Global Variables

static uint16_t SYSTEM_CONFIG_stored = 0;

#define DATA_TYPE_RESULTS ((SYSTEM_CONFIG_stored & ~(SYSTEM_CONFIG_DATA_TYPE_MASK)) >> 6)

// Pin definitions

const int CSpin = 10;

void setup() {

// put your setup code here, to run once:

pinMode(CSpin, OUTPUT);

digitalWrite(CSpin, HIGH); // Deselect the TMAG5170 initially

// SPI.beginTransaction(SPISettings(100000, MSBFIRST, SPI_MODE0));

SPI.begin();

Serial.begin(9600);

// Configure device:

TMAG5170startup();

// Configuration Mode

enterConfigurationMode();

// Enable/disable functionalities and measurements

enableMagChannels(MAG_CH_EN_BITS_XYZ);

enableTemperatureMeasurement();

// Sample Rate

setSampleRate(CONV_AVG_BITS_16X);

// Set ranges magnetic measurement

setRanges(SENSOR_CONFIG_X_RANGE_50mT, SENSOR_CONFIG_Y_RANGE_50mT, SENSOR_CONFIG_Z_RANGE_50mT);

delay(100);

}

void loop() {

// put your main code here, to run repeatedly:

// // Example magnetic sensor temperature read

// float magTemperature = getMeasurementNrmlTEMP();

// // Print magnetic sensor temperature readout

// Serial.print("Magnetic Sensor Temperature: ");

// Serial.print(magTemperature);

// Serial.println(" °C");

// // Example magnetic readout

// float magX = getMeasurementNrmlX();

// // Print magnetic readout

// Serial.print("Magnetic Flux X-component: ");

// Serial.print(magX);

// Serial.println(" mT");

// Some checks

int response = normalReadRegister(X_THRX_CONFIG_ADDRESS);

Serial.print("X_THRX_CONFIG_ADDRESS: ");

Serial.print("Data: 0x");

Serial.println(response, HEX);

int response1 = normalReadRegister(SENSOR_CONFIG_ADDRESS);

Serial.print("SENSOR_CONFIG_ADDRESS: ");

Serial.print("Data: 0x");

Serial.println(response1, HEX);

delay(1000); // Adjust the delay based on your desired reading frequency

}

//****************************************************************************

//****************************************************************************

//

// Note (Matis)

//

// These functions are to 'initiate/connect/communicate' with the hardware.

// They are taken from the TI example code (hal_ex.c) and edited to work in

// this environment

//

//****************************************************************************

//****************************************************************************

void spiSendReceiveArrays(const uint8_t dataTx[], uint8_t dataRx[], const uint8_t byteLength)

{

// Require that dataTx and dataRx are not NULL pointers

assert(dataTx && dataRx);

// Set the nCS pin LOW

digitalWrite(CSpin, LOW);

// Send all dataTx[] bytes on MOSI, and capture all MISO bytes in dataRx[]

int i;

for (i = 0; i < byteLength; i++)

{

dataRx[i] = spiSendReceiveByte(dataTx[i]);

}

// Set the nCS pin HIGH

digitalWrite(CSpin, HIGH);

}

uint8_t spiSendReceiveByte(const uint8_t dataTx)

{

// Remove any residual or old data from the receive FIFO

// Could come later; something along the lines of making sure dataRx[] is empty

// SSI TX & RX

uint8_t dataRx;

dataRx = SPI.transfer(dataTx);

// TODO: can we remove the SSIDataGetNonBlocking() call here and move it to spiSendReceiveArrays()?

// TODO: Add error checking and handling here in case of TX or RX problems...

return dataRx;

}

//****************************************************************************

//****************************************************************************

//

// Note (Matis)

//

// From now on this are functions given in the TI example code (tamg5170_ex.c)

//

//****************************************************************************

//****************************************************************************

//****************************************************************************

//! Initialization function

//!

//! This function MUST be ran at the beginning of any implementation using this

//! example code. This is needed because the SYSTEM_CONFIG register is needed to

//! be tracked and updated accordingly to prevent losing track of the DATA_TYPE

//! in use by the device.

//!

//! If CRC is being disabled per the header definition being enabled, then this

//! function also sends the command to disable CRC on the device as well.

//! NOTE: if CRC is being disabled then the RESET_DEVICE_IN_STARTUP should be

//! enabled as well

//****************************************************************************

void TMAG5170startup()

{

// (OPTIONAL) Provide additional delay time for power supply settling

delayMicroseconds(50);

#ifdef RESET_DEVICE_IN_STARTUP

// SYSTEM_CONFIG_stored will be set to default in this function

resetDevice();

#else

// The default implementation of this initialize function is resetting only

// the SYSTEM_CONFIG register and leaving the other registers unchanged.

writeToRegister( SYSTEM_CONFIG_ADDRESS, SYSTEM_CONFIG_DEFAULT );

SYSTEM_CONFIG_stored = SYSTEM_CONFIG_DEFAULT;

#endif

#ifdef DISABLE_CRC_IN_STARTUP

// Sends command to disable CRC verfication and calculation on device-side

// MUST be called first in implementation for commands from other functions

// to be accepted when DISABLE_CRC_IN_STARTUP is used.

uint8_t dataTx[4] = {0x0F,0x00,0x04,0x07};

uint8_t dataRx[4] = {0};

sendAndReceiveFrame(dataTx,dataRx);

#endif

}

//****************************************************************************

//! Reset Device to Factory Settings

//!

//! This function uses the DeepSleep functions to reset the device's registers back to the

//! default settings outlined in the datasheet. This function also resets the

//! SYSTEM_CONFIG_stored variable to the default value in the enterDeepSleepMode function.

//****************************************************************************

void resetDevice()

{

enterDeepSleepMode(); // Deep Sleep Mode resets the device to its default settings

exitDeepSleepMode();

}

//****************************************************************************

//! Enter Deep Sleep Mode

//!

//! Make sure to use the exitDeepSleepMode function to properly exit Deep Sleep Mode.

//! Deep Sleep Mode can be alternately exited with a short pulse on the CS pin.

//!

//! WILL WORK IN SPECIAL READ MODE, DEEP SLEEP MODE RESETS DEVICE TO FACTORY SETTINGS

//! (EXITS SPECIAL READ MODE)

//****************************************************************************

void enterDeepSleepMode()

{

// Send Write command, Deep Sleep resets device to factory settings so

// an initial register read is not needed (DEVICE_CONFIG default is 0x0000)

writeToRegister( DEVICE_CONFIG_ADDRESS, DEVICE_CONFIG_OPERATING_MODE_DeepSleepMode );

SYSTEM_CONFIG_stored = SYSTEM_CONFIG_DEFAULT;

delayMicroseconds(100);

}

//****************************************************************************

//! Exit Deep Sleep Mode

//! (Use this function instead of a different operation mode change function to

//! exit Deep Sleep mode properly)

//!

//! Exits Deep Sleep Mode by pulsing LOW on the CS pin and waiting for the chip

//! to start up. (t_start_deep_sleep)

//!

//! DOES NOT WORK IN SPECIAL READ MODE [DATA_TYPE field at 0x028-6 does not equal 000b]

//****************************************************************************

void exitDeepSleepMode()

{

// A LOW pulse is needed on CS to exit Deep Sleep Mode (enters Configuration Mode)

csPulse();

#ifdef MAX_DELAYS_IN_OPMODE_CHANGES

delayMicroseconds(500); // max expected delay as given by t_start_deep_sleep (datasheet pg. 10)

#else

delayMicroseconds(260); // typical delay for t_start_deep_sleep at Vcc = 2.3V (datasheet pg. 10)

#endif

}

//****************************************************************************

//****************************************************************************

//

// SPI fucntions

//

//****************************************************************************

//****************************************************************************

//****************************************************************************

//! Send and Receive Frame

//!

//! Takes in the frame to transmit by SPI and the array to put the received frame in

//!

//! dataTx[4] - unint8_t array of length 4 containing the bytes frame to transmit

//! ordered with CRC-containing byte last

//! dataRx[4] - unint8_t array of length 4 of zeroes on input, will have the received

//! frame bytes assigned to it ordered with CRC bits last

//****************************************************************************

void sendAndReceiveFrame(uint8_t dataTx[], uint8_t dataRx[])

{

#ifdef DISABLE_CRC_IN_STARTUP

// When CRC is disabled upon system initialization, the need to calculate

// the dataTx CRC for the TMAG5170 to accept commands is gone at the risk

// of transmission errors being passed through.

spiSendReceiveArrays(dataTx, dataRx, TMAG5170_FRAME_NUM_BYTES);

// Check if SYSTEM_CONFIG was written to and update SYSTEM_CONFIG_stored if so

if ( dataTx[0] == SYSTEM_CONFIG_ADDRESS ) SYSTEM_CONFIG_stored = (dataTx[1] << 8) | dataTx[2];

SYSTEM_CONFIG_stored &= ~(0xC818); // Reserved bits cannot be 1, this ensures the

// stored variable doesn't have them changed

#else

// When CRC is enabled (it is by default), the CRC must be calculated and

// included in dataTx for the TMAG5170 to accept commands.

uint8_t crc = calculateCRC( dataTx );

dataTx[3] = dataTx[3] | crc;

spiSendReceiveArrays(dataTx, dataRx, TMAG5170_FRAME_NUM_BYTES);

// The TMAG5170 also calculates the CRC for the frame it sends back to its

// MCU. The TMAG5170 will purposely return a bad CRC if it received a

// transmitted command with a bad CRC as well. Verifying the CRC of dataRx

// helps confirm if dataTx was received successfully and if dataRx is valid.

if (verifyCRC(dataRx) == 0)

{

// Without GLOBAL_CRC_ERROR_VAR_ENABLED defined or another error response

// implemented, this function will not give any indication that the

// received data has an error

#ifdef SEND_RECIEVE_REDUNDANCY_ENABLED

for ( i = 0; i<4; i++ ) { dataRx[i] = 0 };

spiSendReceiveArrays(dataTx, dataRx, TMAG5170_FRAME_NUM_BYTES);

if ( verifyCRC(dataRx) )

{

// Check if SYSTEM_CONFIG was written to and update SYSTEM_CONFIG_stored if so

if ( dataTx[0] == SYSTEM_CONFIG_ADDRESS ) SYSTEM_CONFIG_stored = (dataTx[1] << 8) | dataTx[2];

SYSTEM_CONFIG_stored &= ~(0xC818); // Reserved bits cannot be 1, this ensures the

// stored variable doesn't have them changed

return;

}

#endif

#ifdef GLOBAL_CRC_ERROR_VAR_ENABLED

crc_error_occurence = 1; // If redundancy is enabled too, the error bit

// only flips if both sent TXs receive bad CRCs

#endif

return; // If a received data CRC error is detected, SYSTEM_CONFIG_stored

// will not be updated under the assumption that whatever command

// sent was not accepted.

}

// Check if SYSTEM_CONFIG was written to and update SYSTEM_CONFIG_stored if so

if ( dataTx[0] == SYSTEM_CONFIG_ADDRESS ) SYSTEM_CONFIG_stored = (dataTx[1] << 8) | dataTx[2];

SYSTEM_CONFIG_stored &= ~(0xC818); // Reserved bits cannot be 1, this ensures the

// stored variable doesn't have them changed

#endif

}

//****************************************************************************

//! Write to Register Function (no CMD sent or value returned)

//!

//! Takes in the address of the register to edit and the 16-bit frame to overwrite it with and writes

//! the input frame to the register.

//!

//! This function replaces the whole register with the input data, make sure the values desired to be

//! unchanged are in the input data_to_write!

//!

//! This function will work in Normal and Special Read Mode.

//!

//! address - uint8_t value from 0x00 to 0x14 containing the register address to write over

//! data_to_write - the 16-bit frame to be written to the register at address.

//****************************************************************************

void writeToRegister(uint8_t address, uint16_t data_to_write)

{

// Check that the input address is in range

assert(address < NUM_REGISTERS);

// Build TX and RX byte arrays

uint8_t dataTx[4] = { 0 };

uint8_t dataRx[4] = { 0 };

// MSB is 0 for WRITE command

dataTx[0] = (address);

dataTx[1] = (data_to_write >> 8);

dataTx[2] = (data_to_write);

dataTx[3] = 0x00;

sendAndReceiveFrame(dataTx, dataRx);

}

//****************************************************************************

//! Full Read Function for Normal Data Mode (DATA_TYPE = 000b)

//!

//! Takes in an output array of length 2, address to read from, and CMD bits to send along,

//! then creates the dataTx array and calls the sendAndReturnFrame function, interpreting

//! dataRx and putting the read register in output[0] and status bits in output[1]

//!

//! output[2] - empty uint16_t array of length 2, output[0] will be assigned the returned register

//! at the given address, output[1] will be assigned the returned status bits.

//! address - uint8_t value from 0x00 to 0x14 containing the register address to read from

//! cmd_bits - uint8_t value from 0x00 to 0x03 containing the CMD0 and CMD1 bits that will be sent

//! in dataTx. LSB is CMD0, next bit is CMD1. (see header file or datasheet pg. 29 for CMD functions)

//****************************************************************************

void normalRead( uint16_t output[], uint8_t address, uint8_t cmd_bits )

{

// Check that the input address is in range

assert(address < NUM_REGISTERS);

// Build TX and RX byte arrays

uint8_t dataTx[4] = { 0 };

uint8_t dataRx[4] = { 0 };

// MSB is 1 for READ command

dataTx[0] = (address | 0x80);

dataTx[1] = 0x00;

dataTx[2] = 0x00;

dataTx[3] = cmd_bits << 4;

sendAndReceiveFrame(dataTx, dataRx);

output[0] = (dataRx[1] << 8) | dataRx[2];

output[1] = (dataRx[0] << 4) | (dataRx[3] >> 4);

}

//****************************************************************************

//! Register-only Read Function for Normal Data Mode (DATA_TYPE = 000b)

//!

//! Takes in address to read from and returns register at address without the status bits or

//! triggering any CMD function (cmd_bits = 0x00).

//!

//! address - uint8_t value from 0x00 to 0x14 containing the register address to read from

//****************************************************************************

uint16_t normalReadRegister( uint8_t address )

{

uint16_t output[2] = { 0 };

normalRead( output, address, 0x00 );

return output[0];

}

// Note (Matis): I have excluded all Special Read Mode capabilities

//****************************************************************************

//****************************************************************************

//

// Change Device Operation Mode

//

// Note (Matis): other modes available in TI example code are Stand-by, Active Measure, Active Trigger, Sleep, Wake and Sleep, Deep Sleep

// Exit Sleep, Exit Wake Up and Sleep, Exit Deep Sleep Modes

//

//****************************************************************************

//****************************************************************************

//****************************************************************************

//! Enter Configuration Mode

//!

//! DOES NOT WORK IN SPECIAL READ MODE [DATA_TYPE field at 0x028-6 does not equal 000b]

//****************************************************************************

void enterConfigurationMode()

{

// To prevent undefined behavior, this function does not perform its operation

// when the DATA_TYPE field (address: 0x028-6) is not set to Normal Read Mode (000b)

if ( DATA_TYPE_RESULTS != DATA_TYPE_RESULTS_NormalMode ) return;

uint16_t input;

// Set OPERATING_MODE (address: 0x006-4) to Configuration Mode (0h)

input = normalReadRegister(DEVICE_CONFIG_ADDRESS);

input = ( input & ~(DEVICE_CONFIG_OPERATING_MODE_MASK) ) | DEVICE_CONFIG_OPERATING_MODE_ConfigurationMode;

writeToRegister( DEVICE_CONFIG_ADDRESS, input );

#ifdef MAX_DELAYS_IN_OPMODE_CHANGES

delayMicroseconds(50); // max expected delay as given by t_start_sleep (datasheet pg. 10)

#endif

}

//****************************************************************************

//****************************************************************************

//

// Notes (Matis)

//

// Functionalities omitted:

// Functions to Configure Trigger Settings

// Threshold Detection + ALERT output Settings

//

//****************************************************************************

//****************************************************************************

//****************************************************************************

//****************************************************************************

//

// Measurement Configuration Functions

//

//****************************************************************************

//****************************************************************************

//****************************************************************************

//! Enable Magnetic Axes for Measurement (also can turn all channels off)

//!

//! Takes in a 4-bit value for the MAG_CH_EN field (0x019-6)

//! mag_ch_en_bits must not be greater than 0x0F

//!

//! When mag_ch_en_bits < 0x08 its three LSBs act as a three bit enable/disable command for ZYX

//! (examples: 0x05 (0101b) => ZX enabled | 0x02 (0010b) => Y enabled)

//!

//! When mag_ch_en_bits >= 0x08 it configures alternative sampling orders along with enabling

//! specific channels (see chart below)

//!

//! | enabled channels || | enabled channels

//! mag_ch_en_bits | + sampling order || mag_ch_en_bits | + sampling order

//! _________________|__________________||__________________|__________________

//! 0x00 none || 0x08 XYX

//! 0x01 X || 0x09 YXY

//! 0x02 Y || 0x0A YZY

//! 0x03 XY || 0x0B ZYZ

//! 0x04 Z || 0x0C ZXZ

//! 0x05 ZX || 0x0D XZX

//! 0x06 YZ || 0x0E XYZYX

//! 0x07 XYZ || 0x0F XYZZYX

//!

//! Definitions for descriptive inputs to this function are provided in the header file.

//!

//! DOES NOT WORK IN SPECIAL READ MODE [DATA_TYPE field at 0x028-6 does not equal 000b]

//****************************************************************************

void enableMagChannels( uint8_t mag_ch_en_bits )

{

// To prevent undefined behavior, this function does not perform its operation

// when the DATA_TYPE field (0x028-6) is not set to Normal Read Mode (000b)

if ( DATA_TYPE_RESULTS != DATA_TYPE_RESULTS_NormalMode ) return;

// Check that inputs are valid

if ( !( mag_ch_en_bits <= 0x0F ) ) return;

uint16_t input;

// Set MAG_CH_EN (0x019-6) to mag_ch_en_bits

input = normalReadRegister(SENSOR_CONFIG_ADDRESS);

input = ( input & ~(SENSOR_CONFIG_MAG_CH_EN_MASK) ) | (mag_ch_en_bits << 6);

writeToRegister( SENSOR_CONFIG_ADDRESS, input );

}

//****************************************************************************

//! Enable Angle Measurement (also can turn off angle measurement)

//!

//! Takes in a 2-bit value for the ANGLE_EN field (0x01F-E) to determine which two

//! axes to measure the angle off of for the on-board CORDIC function in the device.

//!

//! Based on the ANGLE_EN setting, the angle will be calculated using the first axis

//! as the "horizontal" axis (positive side of axis is 0 degrees) and the second as

//! the "vertical" axis (positive side of axis is 90degrees)

//!

//! angle_en_bits can be set to 0x00 to 0x03 to configure these settings for ANGLE_EN:

//! ANGLE_EN value | horizontal axis | vertical axis

//! 0x00 none none -- (angle measurement disabled)

//! 0x01 X Y

//! 0x02 Y Z

//! 0x03 X Z

//****************************************************************************

void enableAngleMeasurement( uint8_t angle_en_bits )

{

// To prevent undefined behavior, this function does not perform its operation

// when the DATA_TYPE field (0x028-6) is not set to Normal Read Mode (000b)

if ( DATA_TYPE_RESULTS != DATA_TYPE_RESULTS_NormalMode ) return;

// Check that inputs are valid

if ( !( angle_en_bits <= 0x03 ) ) return;

// To prevent undefined behavior, this function does not perform its operation

// when the DATA_TYPE field (0x028-6) is not set to Normal Read Mode (000b)

if ( DATA_TYPE_RESULTS != DATA_TYPE_RESULTS_NormalMode ) return;

uint16_t input;

// Set ANGLE_EN (0x01F-E) to mag_ch_en_bits

input = normalReadRegister(SENSOR_CONFIG_ADDRESS);

input = ( input & ~(SENSOR_CONFIG_ANGLE_EN_MASK) ) | (angle_en_bits << 14);

writeToRegister( SENSOR_CONFIG_ADDRESS, input );

}

//****************************************************************************

//! Enable Temperature Measurement

//!

//! Begins Temperature Measurements by changing the T_CH_EN field in the

//! DEVICE_CONFIG to 1b.

//****************************************************************************

void enableTemperatureMeasurement() {

uint16_t input = normalReadRegister(DEVICE_CONFIG_ADDRESS);

input &= ~(DEVICE_CONFIG_T_CH_EN_MASK);

input |= DEVICE_CONFIG_T_CH_EN_TemperatureChannelEnabled;

writeToRegister( DEVICE_CONFIG_ADDRESS, input );

}

//****************************************************************************

//! Disable Temperature Measurement

//!

//! Ends Temperature Measurements by changing the T_CH_EN field in the

//! DEVICE_CONFIG to 0b.

//****************************************************************************

void disableTemperatureMeasurement() {

uint16_t input = normalReadRegister(DEVICE_CONFIG_ADDRESS);

input &= ~(DEVICE_CONFIG_T_CH_EN_MASK);

input |= DEVICE_CONFIG_T_CH_EN_TemperatureChannelDisabled;

writeToRegister( DEVICE_CONFIG_ADDRESS, input );

}

//****************************************************************************

//! Set Sampling Rate (configure the amount of additional samples to reduce noise/increase resolution)

//!

//! CONV_AVG_bits - what value to set for the CONV_AVG (0x00E-C) value (from datasheet pg. 34):

//! | num. samples | 3-axes speed | 1-axis speed |

//! 0x00 - 1x 10.0Ksps 20Ksps

//! 0x01 - 2x 5.7Ksps 13.3Ksps

//! 0x02 - 4x 3.1Ksps 8.0Ksps

//! 0x03 - 8x 1.6Ksps 4.4Ksps

//! 0x04 - 16x 0.8Ksps 2.4Ksps

//! 0x05 - 32x 0.4Ksps 1.2Ksps

//****************************************************************************

void setSampleRate( uint8_t CONV_AVG_bits )

{

uint16_t input;

// Set CONV_AVG (0x00E-C) to CONV_AVG_bits

input = normalReadRegister(DEVICE_CONFIG_ADDRESS);

input = ( input & ~(DEVICE_CONFIG_CONV_AVG_NUM_MASK) ) | (CONV_AVG_bits << 12);

writeToRegister( DEVICE_CONFIG_ADDRESS, input );

}

//****************************************************************************

//! Set Ranges for X, Y, and Z axes

//!

//! Sets the X, Y, and Z_RANGE fields in the SENSOR_CONFIG register to the bits

//! determined by the function inputs.

//!

//! x_range_bits - bits for X_RANGE field (must be no greater than 0x02)

//! y_range_bits - bits for Y_RANGE field (must be no greater than 0x02)

//! z_range_bits - bits for Z_RANGE field (must be no greater than 0x02)

//!

//! According to the TMAG5170 version used, the mT range for the bits are as follows:

//!

//! *_range_bits | TMAG5170A1 | TMAG5170A2

//! input | mT range value | mT range value

//! _________________|________________|________________

//! 0x00 | 50 mT | 150 mT

//! 0x01 | 25 mT | 75 mT

//! 0x02 | 100 mT | 300 mT

//****************************************************************************

void setRanges( uint8_t x_range_bits, uint8_t y_range_bits, uint8_t z_range_bits )

{

// To prevent undefined behavior, this function does not perform its operation

// when the DATA_TYPE field (0x028-6) is not set to Normal Read Mode (000b)

if ( DATA_TYPE_RESULTS != DATA_TYPE_RESULTS_NormalMode ) return;

// Check that inputs are valid

if ( x_range_bits > 0x02 || y_range_bits > 0x02 || z_range_bits > 0x02 ) return;

uint16_t input = normalReadRegister(SENSOR_CONFIG_ADDRESS) & ~(SENSOR_CONFIG_FULL_RANGE_MASK);

input |= (z_range_bits << 4) | (y_range_bits << 2) | x_range_bits;

writeToRegister( SENSOR_CONFIG_ADDRESS, input );

}

//****************************************************************************

//****************************************************************************

//

// Get Results/Measurement Functions (Normal Read Mode)

//

//****************************************************************************

//****************************************************************************

//****************************************************************************

//! Get and return the *_CH_RESULT (or TEMP_RESULT for T) register for an axis/measurement

//!

//! These functions explicitly return the unsigned 16-bit register of their respective

//! measurement address.

//****************************************************************************

uint16_t getXresult() { return normalReadRegister(X_CH_RESULT_ADDRESS); }

uint16_t getYresult() { return normalReadRegister(Y_CH_RESULT_ADDRESS); }

uint16_t getZresult() { return normalReadRegister(Z_CH_RESULT_ADDRESS); }

uint16_t getTEMPresult() { return normalReadRegister(TEMP_RESULT_ADDRESS); }

uint16_t getANGLEresult() { return normalReadRegister(ANGLE_RESULT_ADDRESS); }

uint16_t getMAGresult() { return normalReadRegister(MAGNITUDE_RESULT_ADDRESS); }

// NOTE: These functions returned the unsigned integer corresponding to the register value

// for easier bit operations. To convert the unsigned using the equations used in the

// example code, it must be casted to an signed integer.

//****************************************************************************

//! Get Magnetic Results Registers (Normal Read Mode)

//!

//! In 32-bit normal read mode:

//! Takes in a size 3 array of int16_t values and assigns it the the

//! three *_CH_RESULT registers. (order XYZ)

//!

//! INPUT ARRAY MUST BE OF LENGTH 3

//!

//! NOTE: The uint16_t variables returned by the get*result functions are casted

//! into int16_t variables for use with the other provided functions that take

//! signed integers.

//!

//! DOES NOT WORK IN SPECIAL READ MODE [DATA_TYPE field at 0x028-6 does not equal 000b]

//****************************************************************************

void getMagResultsRegistersNrml( int16_t meas_arr[] )

{

meas_arr[0] = (int16_t) getXresult();

meas_arr[1] = (int16_t) getYresult();

meas_arr[2] = (int16_t) getZresult();

}

//****************************************************************************

//! Get X-axis Magnetic Flux Measurement in mT

//!

//! Returns a float containing the mT magnetic flux measurement converted from the

//! X_CH_RESULT register.

//****************************************************************************

float getMeasurementNrmlX()

{

uint16_t range = getXrange();

int16_t data = getXresult(); // separate variable used to cast to a signed int

// for the float cast to work correctly

return (((float) data) / 32768) * range;

}

//****************************************************************************

//! Get Y-axis Magnetic Flux Measurement in mT

//!

//! Returns a float containing the mT magnetic flux measurement converted from the

//! Y_CH_RESULT register.

//****************************************************************************

float getMeasurementNrmlY()

{

uint16_t range = getYrange();

int16_t data = getYresult(); // separate variable used to cast to a signed int

// for the float cast to work correctly

return (((float) data) / 32768) * range;

}

//****************************************************************************

//! Get Z-axis Magnetic Flux Measurement in mT

//!

//! Returns a float containing the mT magnetic flux measurement converted from the

//! Z_CH_RESULT register.

//****************************************************************************

float getMeasurementNrmlZ()

{

uint16_t range = getZrange();

int16_t data = getZresult(); // separate variable used to cast to a signed int

// for the float cast to work correctly

return (((float) data) / 32768) * range;

}

//****************************************************************************

//! Get Temperature Measurement in degrees C (Normal Read Mode)

//!

//! Currently the 'Typical' Electrical Characteristics (ECHAR) of the device are set

//! in the header file. If the device has been calibrated and different ECHAR values

//! are found, please edit the ECHAR values in the header file for more accurate

//! temperature measurement. The header file also contains more information on ECHAR values.

//****************************************************************************

float getMeasurementNrmlTEMP()

{

uint16_t tADC_T = getTEMPresult();

float temp_val = ECHAR_T_SENS_T0 + ( ((((float) tADC_T) - ECHAR_T_ADC_T0)) / ECHAR_T_ADC_RES );

return temp_val;

}

//****************************************************************************

//! Get Internal Angle Measurement in Degrees

//!

//! Returns a float containing the degree value converted from the ANGLE_RESULT register.

//! The value corresponds to the calculated angle created by the two magnetic flux axis

//! measurements selected by the ANGLE_EN bits.

//!

//! For the angle to be properly measured, the two axes selected by ANGLE_EN must share the

//! same selected range.

//****************************************************************************

float getMeasurementNrmlANGLE()

{

uint16_t data = getANGLEresult();

float angle = ( (float) data / 16 );

return angle;

}

//****************************************************************************

//! Get Internal Magnitude Measurement in mT

//!

//! Returns a float containing the mT value converted from the MAGNITUDE_RESULT register.

//! The value corresponds to the calculated magnitude created by the two magnetic flux axis

//! measurements selected by the ANGLE_EN bits.

//!

//! For the magnitude to be properly measured, the two axes selected by ANGLE_EN must share the

//! same selected range.

//****************************************************************************

float getMeasurementNrmlMAG()

{

uint16_t data = getMAGresult();

// TODO: verify magnitude correlates with expected

float magnitude = (((float) data)/8192) * getMAGrange() * 4;

return magnitude;

}

//****************************************************************************

//! Get Magnetic Measurements in mT (Normal Read Mode)

//!

//! In 32-bit normal read mode:

//! Takes in a size 3 array of floats and updates its measurements of the

//! three magnetic axes in mT. (order XYZ)

//!

//! INPUT ARRAY MUST BE SIZE 3 (or at least have meas_arr to meas_arr + 2 within scope)

//!

//! DOES NOT WORK IN SPECIAL READ MODE [DATA_TYPE field at 0x028-6 does not equal 000b]

//****************************************************************************

void getMagMeasurementsNrml( float meas_arr[] )

{

uint8_t i;

// Array to store ranges for coordinates in the order XYZ

uint16_t ranges[3] = {50,50,50}; // The default value for coordinate ranges is 50 mT (A1)

ranges[0] = getXrange();

ranges[1] = getYrange();

ranges[2] = getZrange();

int16_t data;

for (i=0; i<3; ++i)

{

data = normalReadRegister(X_CH_RESULT_ADDRESS + i); // read in

meas_arr[i] = (((float) data) / 32768) * ranges[i];

}

}

//****************************************************************************

//****************************************************************************

//

// Get Range Functions

//

//****************************************************************************

//****************************************************************************

//****************************************************************************

//! Get and return the integer value of the X_RANGE bits for an axis

//!

//! Returns an unsigned 16-bit integer value of the X axis range in mT.

//****************************************************************************

uint16_t getXrange()

{

// Get SENSOR_CONFIG and isolate X_RANGE bits.

uint16_t config = normalReadRegister(SENSOR_CONFIG_ADDRESS) & SENSOR_CONFIG_X_RANGE_MASK;

uint16_t range;

if ( getVersion() == 1 )

{

// range values for TMAG5170A2

range = 150;

if ( config == 0x0001 ) range = 75; // If examined bits equal 01b, range is set to 75 mT (for A2)

else if ( config == 0x0002 ) range = 300; // If examined bits equal 10b, range is set to 300 mT (for A2)

}

else

{

// range values for TMAG5170A1

range = 50;

if ( config == 0x0001 ) range = 25; // If examined bits equal 01b, range is set to 25 mT (for A1)

else if ( config == 0x0002 ) range = 100; // If examined bits equal 10b, range is set to 100 mT (for A1)

}

return range;

}

//****************************************************************************

//! Get and return the integer value of the Y_RANGE bits for an axis

//!

//! Returns an unsigned 16-bit integer value of the Y axis range in mT.

//****************************************************************************

uint16_t getYrange()

{

// Get SENSOR_CONFIG and isolate Y_RANGE bits, shifting them to LSB.

uint16_t config = normalReadRegister(SENSOR_CONFIG_ADDRESS) & SENSOR_CONFIG_Y_RANGE_MASK >> 2;

uint16_t range;

if ( getVersion() == 1 )

{

// range values for TMAG5170A2

range = 150;

if ( config == 0x0001 ) range = 75; // If examined bits equal 01b, range is set to 75 mT (for A2)

else if ( config == 0x0002 ) range = 300; // If examined bits equal 10b, range is set to 300 mT (for A2)

}

else

{

// range values for TMAG5170A1

range = 50;

if ( config == 0x0001 ) range = 25; // If examined bits equal 01b, range is set to 25 mT (for A1)

else if ( config == 0x0002 ) range = 100; // If examined bits equal 10b, range is set to 100 mT (for A1)

}

return range;

}

//****************************************************************************

//! Get and return the integer value of the Z_RANGE bits for an axis

//!

//! Returns an unsigned 16-bit integer value of the Z axis range in mT.

//****************************************************************************

uint16_t getZrange()

{

// Get SENSOR_CONFIG and isolate Z_RANGE bits, shifting them to LSB.

uint16_t config = normalReadRegister(SENSOR_CONFIG_ADDRESS) & SENSOR_CONFIG_Z_RANGE_MASK >> 4;

uint16_t range;

if ( getVersion() == 1 )

{

// range values for TMAG5170A2

range = 150;

if ( config == 0x0001 ) range = 75; // If examined bits equal 01b, range is set to 75 mT (for A2)

else if ( config == 0x0002 ) range = 300; // If examined bits equal 10b, range is set to 300 mT (for A2)

}

else

{

// range values for TMAG5170A1

range = 50;

if ( config == 0x0001 ) range = 25; // If examined bits equal 01b, range is set to 25 mT (for A1)

else if ( config == 0x0002 ) range = 100; // If examined bits equal 10b, range is set to 100 mT (for A1)

}

return range;

}

//****************************************************************************

//! Get Range used for Magnitude register mT conversion

//!

//! Returns the range selected by the first ANGLE_EN axis. For proper use of the magnitude register

//! both of the ANGLE_EN axes must share the same range.

//!

//! If ANGLE_EN is disabled the function will still return the X-axis range.

//****************************************************************************

uint16_t getMAGrange()

{

uint16_t angle_en = normalReadRegister(SENSOR_CONFIG_ADDRESS) & SENSOR_CONFIG_ANGLE_EN_MASK;

if ( angle_en == SENSOR_CONFIG_ANGLE_EN_YZ ) return getYrange();

else return getXrange();

}

//****************************************************************************

//****************************************************************************

//

// Get Device Info Functions

//

//****************************************************************************

//****************************************************************************

//****************************************************************************

//! Get TMAG5170 Version (A1 or A2)

//!

//! Sends a read command for TEST_CONFIG and returns the VER field bit.

//! VER == 0b --> TMAG5170A1 | VER == 1b --> TMAG5170A2

//****************************************************************************

uint8_t getVersion()

{ return (normalReadRegister(TEST_CONFIG_ADDRESS) & TEST_CONFIG_VER_MASK) >> 4; }

//****************************************************************************

//! Check if CRC is enabled

//!

//! Sends a read command for TEST_CONFIG and returns the whether the CRC_DIS field

//! corresponds to an enabled CRC or not. (1b == enabled)

//****************************************************************************

uint8_t isCRCenabled()

{

return ((normalReadRegister(TEST_CONFIG_ADDRESS) & TEST_CONFIG_CRC_DIS_MASK) >> 2) == 0;

}

//****************************************************************************

//****************************************************************************

//

// Notes (Matis)

//

// Functionalities omitted:

// Offset and Gain Correction Functions

// Special 32-bit Data Read Functions (DATA_TYPE != 000b)

// Supplemental Functions

// Helper Functions (except CRC Functions)

//

//****************************************************************************

//****************************************************************************

//****************************************************************************

//****************************************************************************

//

// CRC Functions from Helper Functions

//

//****************************************************************************

//****************************************************************************

//****************************************************************************

//! Calculate CRC for SPI data frame

//!

//! Takes in an array containing a SPI data frame (MSB to LSB) with the CRC bits

//! all set to ZERO and calculates and returns the CRC for that data frame.

//****************************************************************************

uint8_t calculateCRC( uint8_t data[] )

{

int i = 0;

uint8_t crc = 0x00;

uint32_t n;

// Build TX and RX byte array

uint8_t d[32] = { 0 };

n = (data[0] << 24)|(data[1] << 16)|(data[2] << 8)|(data[3]);

while (n>0)

{

d[i] = n&1;

n = n>>1;

i++;

}

crc |= d[30] ^ d[26] ^ d[25] ^ d[24] ^ d[23] ^ d[21] ^ d[19] ^ d[18] ^ d[15] ^ d[11] ^ d[10] ^ d[9] ^ d[8] ^ d[6] ^ d[4] ^ d[3] ^ d[0] ^ 1;

crc |= (d[31] ^ d[30] ^ d[27] ^ d[23] ^ d[22] ^ d[21] ^ d[20] ^ d[18] ^ d[16] ^ d[15] ^ d[12] ^ d[8] ^ d[7] ^ d[6] ^ d[5] ^ d[3] ^ d[1] ^ d[0] ^ 1 ^ 1) << 1;

crc |= (d[31] ^ d[28] ^ d[24] ^ d[23] ^ d[22] ^ d[21] ^ d[19] ^ d[17] ^ d[16] ^ d[13] ^ d[9] ^ d[8] ^ d[7] ^ d[6] ^ d[4] ^ d[2] ^ d[1] ^ 1 ^ 1) << 2;

crc |= (d[29] ^ d[25] ^ d[24] ^ d[23] ^ d[22] ^ d[20] ^ d[18] ^ d[17] ^ d[14] ^ d[10] ^ d[9] ^ d[8] ^ d[7] ^ d[5] ^ d[3] ^ d[2] ^ 1) << 3;

return crc;

}

//****************************************************************************

//! Verify CRC in SPI data frame

//!

//! Takes in an array containing a SPI data frame (MSB to LSB) and checks if the

//! CRC bits (according to their locations for the TMAG5170) are correct according

//! to the CRC calculation algorithm.

//****************************************************************************

uint8_t verifyCRC( uint8_t data[] )

{

uint8_t crc_received = data[3] & 0x0F;

data[3] &= ~(0x0F); // the CRC bits of the data must be 0000b to calculate its CRC correctly

uint8_t crc_calc = calculateCRC(data);

data[3] |= crc_received; // the previously removed CRC bits are reinserted

return crc_received == crc_calc;

}

//****************************************************************************

//! Pulse CS function

//!

//! This function pulses LOW on the GPIO pin connected to the CS pin of the TMAG5170

//! for 2 us. (set pin to HIGH afterwards)

//!

//! Can be used to trigger conversion for TRIGGER_MODE set to 'at CS pulse'

//****************************************************************************

void csPulse()

{

digitalWrite(CSpin, LOW);

delayMicroseconds(2);

digitalWrite(CSpin, HIGH);

}

The beginning is the most relevant where I attempt to communicate via SPI and after that the rest of the functions are the ones given by TI.