Hello -

I am considering the TMP114 for my application because of the low thermal resistance between the junction and top case. Are there any guidelines for how close to the object the TMP114 should be placed? I guess closer is better, but wonder if you can point me to any documentation that helps quantify this. I am also considering a non-conductive thermal paste between the case and the object to be sensed and wonder if there is any guidance on this approach. I did see the post about using thermal epoxy and the associated errors that can introduce. Are there any concerns with using thermal paste as an interface material?

Regarding accuracy, I have a question about Figure 7-1 of the datasheet. Can I consider the temperature error to follow the black line when averaging is turned on for sample rates of 31.25ms - 2s?

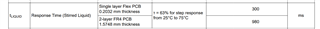

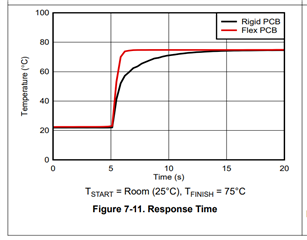

Regarding response time, can I consider the parameter (tLIQUID Response Time (Stirred Liquid)) to be represented by Figure 7-11?

Thank you,

J