Hello, I am seeing Time Constant numbers from the LDC_Tools-ext51 spreadsheet that seem to be differing from the guideline given in the LDC1101 datasheet section 9.1.5, 9.1.6.

Constants used in the below calculations are as follows

Vamp = 0.6V ( specified in datasheet)

fsensormin = 4.03MHz (calculated in spreadsheet, agrees with real world measurement)

Rpmin = 750 ohms (set in spreadsheet based on my finding 1066 ohms real world Rp with maximum metal by VNA measurement)

Time constant 1 setting (refer to datasheet Section 9.1.5)

R1*C1=sqrt(2)/(pi*Vamp*fsensormin)

R1*C1=sqrt(2)/(pi*0.6*4e6) = 1.876e-7

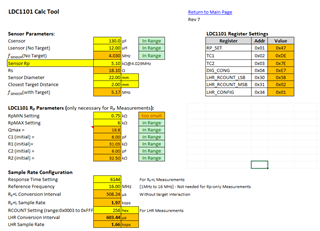

Calculator chosen values are [R1C1]= 0xDE

R1=b1101 = 251k ohms; C1 = b11 = 6pF

R1*C1(programmed) = 1.5e-6

Since 1.876e-7 does not equal 1.5e-6, I'm not sure whether to trust the calculated number in my application.

Time constant 2 setting (refer to datasheet Section 9.1.6)

R2*C2=2*Rpmin*Csensor

R2*C2=2*750*130e-12 = 9.75e-8

Calculator chosen values are [R2C2]= 0x7E

R2=b111110 =43.26k ohms ; C2=b01 = 6pF

R2*C2 (programmed) = 2.6e-7

Since 9.75e-8 does not equal 2.6e-7, I'm not sure whether to trust the calculated number in my application.

Please also note that I think there is a typo in the datasheet, as it refers to TC1 being programmed in the 0x03 register, but it should be 0x02

R1 is the programmed setting for TC1.R1 (register 0x03-bits[4:0]), and

• C1 is the programmed setting for TC1.C1 (register 0x03-bits[7:6])