Hey,

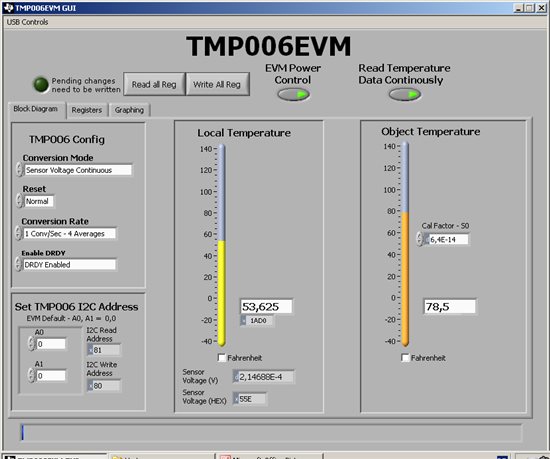

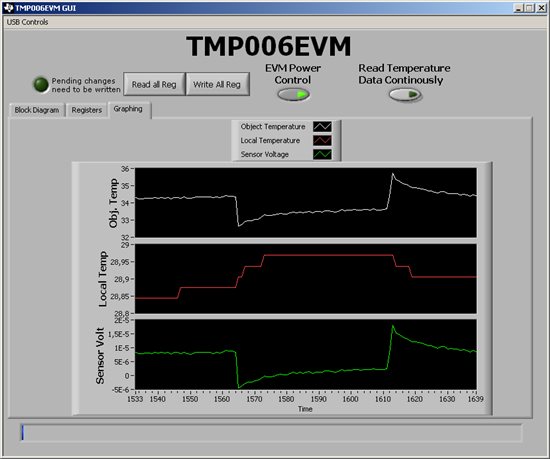

I am from Germany and got a problem with the TMP006EVM accurancy. I want to measure the temperature of a rotating system by using the TMP006EVM. The distance between the TMP006EVM and the object is 2-3mm. My problem is, that the system is not all the time rotating. It stops, accelerates, breaks. Everytime, when it stops the temperature falls within a few seconds and rises within a few seconds, when the system starts again. Even, if I just puff a bit, this thermal behaviour starts. When I puff with warm air, the temperature falls, with cold air, it raises.

I also got a problem with calculating the object temperature. When I use the given parameters (object voltage, local temperature), my calculated object temperature is always too low. At the given example my calculated temperature is: 75,51 °C

What is the physical property? And how can I solve the problem?