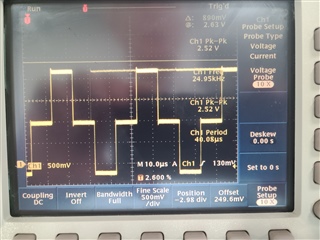

GetCapacitance return value <nil> cap 1.2263946044810243

GetCapacitance return value <nil> cap 0.14561423563481177

GetCapacitance return value <nil> cap 0.02596784026825179

GetCapacitance return value <nil> cap 0.034503124523700655

GetCapacitance return value <nil> cap 0.01764212772443225

GetCapacitance return value <nil> cap 0.02773967383020881

GetCapacitance return value <nil> cap 0.020709495503734188

GetCapacitance return value <nil> cap 0.011869379667733578

GetCapacitance return value <nil> cap 0.0034865112025605854

GetCapacitance return value <nil> cap 0.017604023776863282

GetCapacitance return value <nil> cap 0.030006858710562415

GetCapacitance return value <nil> cap 0.004381953970431337

GetCapacitance return value <nil> cap 0.014022252705380277

GetCapacitance return value <nil> cap 0.013260173754000914

GetCapacitance return value <nil> cap 1.2303193110806279