Other Parts Discussed in Thread: HDC3020,

Dear expert,

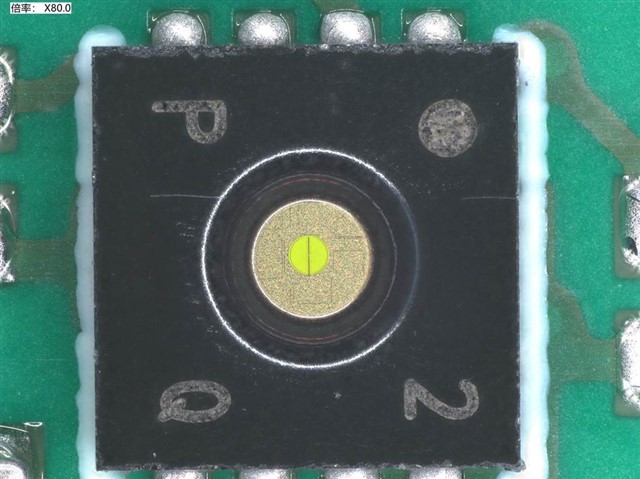

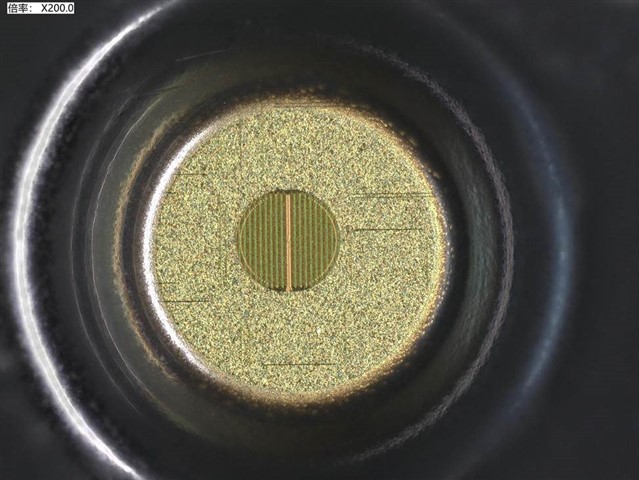

Customer HDC3020 is already in mass production. But randomly, there is some HDC3020 report abnormal RH. After 24 hours back, the HDC3020 become normal. Customer doubt there is some contamination, but they didn't find any contamination at the opening of the humidity sensor element. They wander whether they can ship some unit to BU to help them check whether these HDC3020 is polluted?

And does BU recommend them to program Integrated Heater during to solve this issue at production line? Is there any guide line to use Integrated Heater?

Thanks