Tool/software:

Dear TI,

We're using the DRV5012 on a quadrature encoder for a 12V micro DC motor with a magnet disc that offers 3 pulses per revolution (PPR), i.e. 6 poles. The no load speed is specified at 20000 RPM but measuring with a tachometer yields approximately 19400RPM, FWIW. Given 20000 RPM, this results in 333,33 revolutions per second. At 3 PPR this yields 333,33 x 3 = 1000 PPS or Hertz, multiplying this times 2 (Nyquist) yields 2 kHz hence the 2.5 kHz of the DRV5012 should be sufficient to be able to measure the 1 kHz signal.

Now, my first question is: can I configure the DRV5012 in some way, with higher voltage possibly, to end up in the region 2.5 - 4.7 kHz and how can I test this? Currently the encoder is already powered with a 5V power supply.

In reality we are observing some issues with this encoder however (see screen capture below):

- Channel A seems to have missed a pulse though the small pulse width before is 430 us wide, which proves that the DRV5012 can measure at 2.325 kHz. In order to have aliasing the motor would have to spin at 23250 RPM, which according to the tachometer, the motor doesn't.

- The phase of the A & B signal also almost seems to be in sync while the hall sensors are correctly placed at 90 degrees, which at 3 PPR is correct (half a pole distance of 30 deg + a whole multiple of the pole distance of 90 deg).

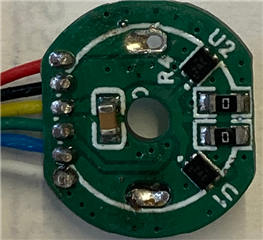

This is a picture of the board:

My second question is: would you recognize anything that we're missing here? Is there something wrong with the layout of the board?

Any support would be much appreciated.

Thanks in advance,

Jelle