Other Parts Discussed in Thread: TMP461

Tool/software:

Hello,

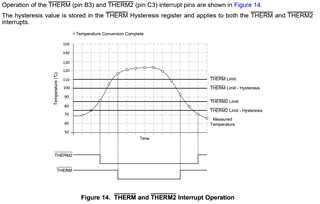

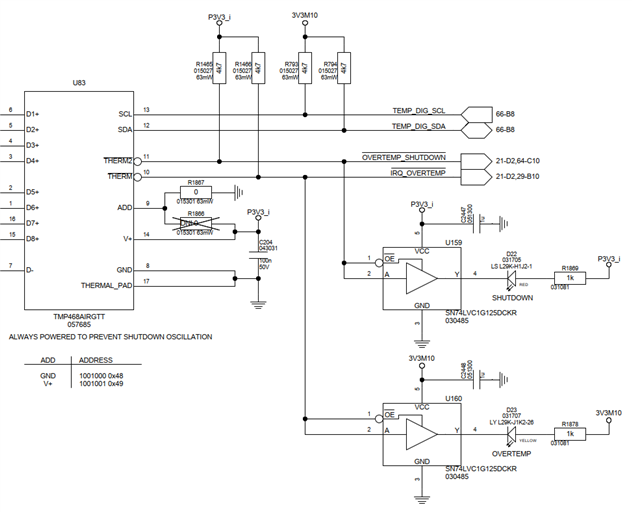

We use the TMP468 to monitor critical components for over-temp condition, and turn power off to our board if the temp is exceeded. Since we need to keep the board powered-down until it actually cools down, the TMP468, and THERM/THERM2 pullups are powered from an always-on supply. When it cools down, we expect the THERM or THERM2 output to stop driving low after the hysteresis setting is crossed.

Unfortunately, on some of our boards, the THERM2 output appears to get stuck driving low, long after the board has cooled, and remains this way until a power-cycle of the TMP468. Is there a setting that could cause the THERM2 output to get stuck driving low?

In the above circuit, only the 3V3_i power is always on. The other power rails are shut down along with the board.