Hello E2E Community,

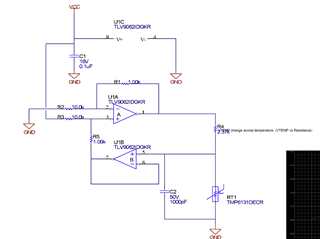

We are evaluating low-cost alternatives to the typical voltage divider configuration when using the TMP61-Q1 in our application. Our setup involves a cable distance of 1 meter from the sensor to the MCU board, and we anticipate potential noise issues. We plan to use RC based LPF before ADC input - R:10kOhm & C:0.1uF along with ADC Hardware oversampling of 1024 samples.

Specifically, we seek guidance on the following points:

-

Is it feasible to use the TMP61-Q1 with a simple 10kΩ bias resistor, given the dynamic range of 1.3V to 2.1V, in an environment with 1-meter long cables?

-

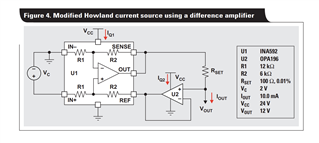

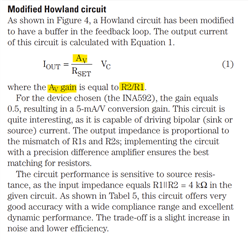

Would using components like the LM334 or TL432LI as a current source provide a more reliable and noise-immune configuration compared to the standard voltage divider approach?

- For soldering what is the maximum temperature the leads can sustain? Can brief temperature of 250'C brazing operation be acceptable for these sensors (as standard with RTDs)?

- Can we install 2 x TMP61 sensors in parallel to lower the offset voltage & then add gain of 2 to improve the dynamic range using? Is this even a feasible line of thought?

Additionally, we face extreme space constraints and prefer to minimize the use of additional components, particularly passive components.

We are also interested in low-cost current source options from TI that can help optimize the implementation of the TMP61-Q1 in our use case.

Your insights and recommendations would be highly valuable for our decision-making process and to ensure the reliability and accuracy of our temperature monitoring system.

Thank you for your support.