Other Parts Discussed in Thread: HDC3020

Tool/software:

HI TI

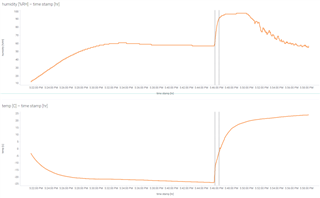

My current device is equipped with an HDC3022. The usage scenario of my device is to monitor a cargo in a cold storage. But when the equipment is taken out of the cold storage, it always carries condensed water. Affects normal use.

I saw in the spec that it is necessary to continuously detect the dew point to determine the condensate water, and judge the condensate water based on the dew point.

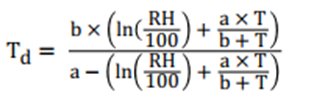

The calculation formula for dew point  mentioned in the document ''Using relative humility to derive vapor pressure, Dew Point, Absolute Humidity, and Enthalpy. '' Where T refers to the air temperature.

mentioned in the document ''Using relative humility to derive vapor pressure, Dew Point, Absolute Humidity, and Enthalpy. '' Where T refers to the air temperature.

But my device has just been taken out of the cold storage, and it must be cold. At first, the device can only measure its own temperature and cannot measure the temperature of the air outside the cold storage.

That is to say, the current HDC3022 cannot know the dew point temperature outside the cold storage. So how can I determine if condensation has occurred?

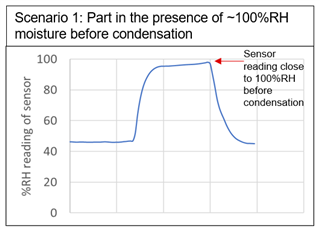

I also saw in the ''How TI Humidity Sensors Remove Device Condensation Using On Chip Heaters '' document that detecting dew point and temperature (dew point is unknown to my device), as well as turning on the heater when the relative humidity becomes too high.

What is the threshold for relative humidity that should be set? How many minutes is suitable for heating?

。Could you post this picture again?

。Could you post this picture again?