Tool/software:

TI Team,

We are developing source code to interface HDC3022DEJR sensor. Our application is design transmitter, battery operated logger with better accuracy in pharma application, Stability Chamber and warehouse.

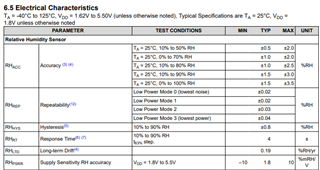

1. After interfacing we found that the sensor readings are not matching with the accuracy mentioned. We are using Rotronics Hygro clip model (+/-0.2°C and +/-0.8%RH Accuracy).

2. What is the life of sensor with respect to its accuracy and its quality.

3. Does it has drift issue in high humidity application like stability chambers, were its humidity reaches to 100%RH after turning off.

4. We selected PTFE filter model to avoid any contamination issue and also it is IP67 rated sensor.

Thanks and Regards