Tool/software:

Hello,

we are dealing with quite the same issues as described in the linked thread:

OPT3101: Deviation with temperature

Is there a solution to handle the temperature calibration on a per-design basis?

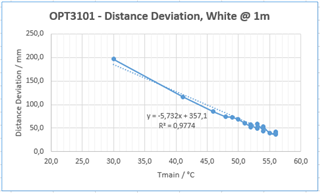

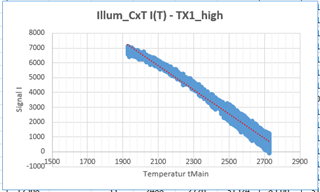

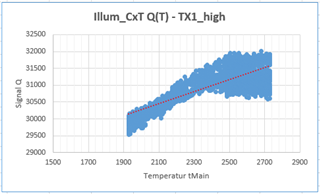

Next to reproducibility and long-term stability of the temperature calibration, we are dealing with distance deviations at faster temperature changes.

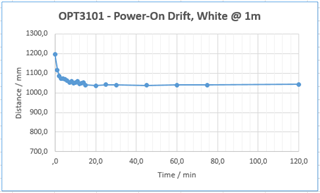

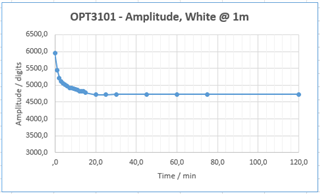

E.g. after Power-on reset, we observe a big distance deviation (> 15%) at first, until the system is thermally balanced.

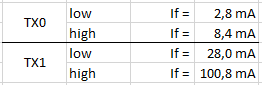

Similarly, such a deviation can be introduced when the LED current is switching in (Super-)HDR-mode.

Furthermore, an air-flow can cause faster temperature changes.

How can such influences be handled?

Thank you.