Other Parts Discussed in Thread: TMAG5253, DRV5055,

Tool/software:

Hello,

I am working on an angular position sensor solution using a TI DRV5053VAQDBZR and a TI XTR117AIDGKR 4-20mA Current-Loop Transmitter. I have been working from primarily the following TI resources:

- Introduction to Hall-Effect Sensors

- Absolute Angle Measurements for Rotational Motion Using Hall-Effect Sensors

- Linear Hall-Effect Sensor Angle Measurement Theory, Implementation, and Calibration

- TI Magnetic Sense Simulator (TIMSS)

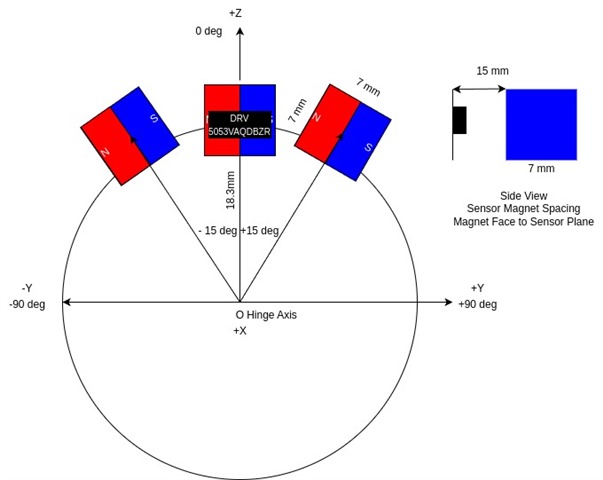

The objective is to measure angular position within ±15° (30 ° arc) with 0° as center. The hall sensor will output to the Current-Loop Transmitter which further outputs into an 12bit ADC. The design intention is to achieve about 1/10 of a degree measurement along the ±15° (30 ° arc).

The mechanical setup is represented as follows:

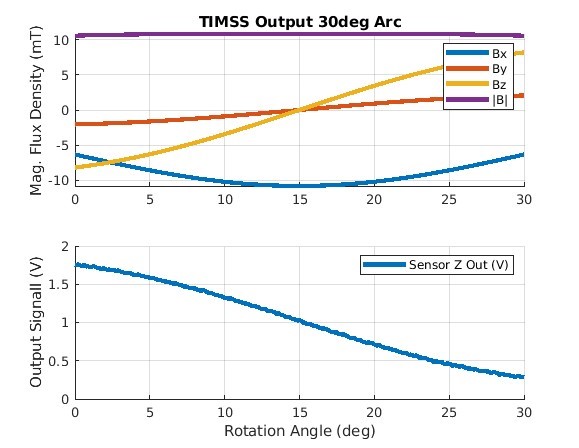

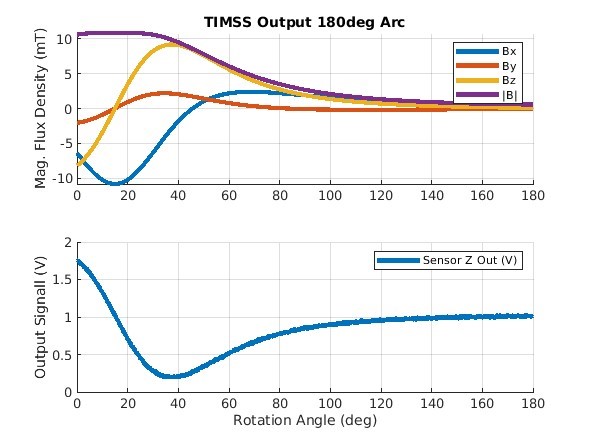

I have made myself familiar with TIMSS and replicated the mechanical/geometric setup above with the intended DRV5053VAQDBZR sensor powered with VCC=5V and assumed a N35 grade 7 x 7 x 7 mm magnet. The output of TIMSS for a 30 deg arc as well as a 180 deg arc result as follows:

I am confessedly out of my element as I have never worked with hall sensors and magnets at this level of design and would appreciate help, even criticism on part selections made thus far, with confusions I have from the above referenced documents.

- The documents often suggest that measuring angular position with a single sensor is achievable but most of the examples or discussion seem to emphasizes two sensor rather than just one. Is there any reason why the selected hall sensor would not be a good choice for measuring angular position within the 30 deg range at the intended resolution? I am treating the 12 bit ADC as if I am only getting 8 bits out of it BTW.

- I am unclear about the choice of magnet for this application. In some instances the documents suggest block magnets as "OK" for angular position but in other places suggest "diametric disc magnets". The best I can gather so far is that this may be related to the magnetic flux density *shape" from the magnet center line. To add to my confusion is that a cube magnet seems like it would be a better mechanical choice during installation compared to a disc magnet which is free to spin during instillation i.e. in cube case alignment of the magnet with the sensor is easier than the disc. Just how important or different would a cube or disc magnet choice be for this application?

- The biggest confusion I have is on calibration. There are so may options in the implementation guide. I cannot peel away a good choice although the LUT method is most appealing so far I have been testing out the Peak Calibration Implementation but I get hung up on what to do since I want to limit my calibration to ±15° (30 ° arc). It seems like this method suggests that data must be collected on a ±90° (180 ° arc) for use with arcsin() but this seems like it would just complicate the code on the MCU/ADC side of the house. I am seem to think that on a ±15° (30 ° arc) I should be able to calibrate and expect better "sensor behavior" on such a limited range. Any help or guidance on the best way to calibrate that may lead to the adoption of Peak Calibration with LUT in our application would be appreciated.

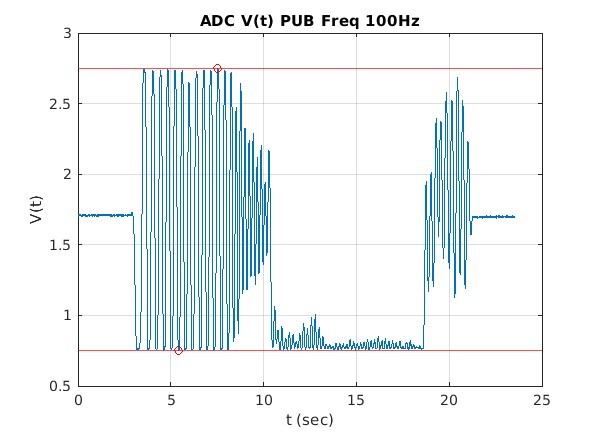

Here is example data collected from "manual excitation" of the mechanical system post current-loop transmitter. The plot shows 100Hz ADC data with a 16 sample average. My next steps are trying to calibrate the sensor correctly for the intended angular range.