Tool/software:

Hello TI,

in a new project, I have to replace a level sensor design that uses hall switches. The goal is to get a continuous fluid level value..

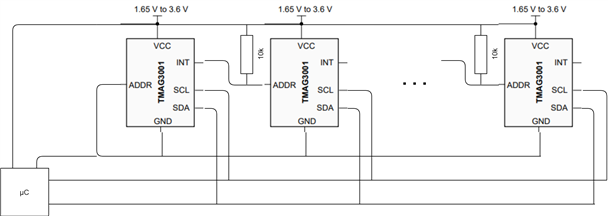

Depending on the length of the device, I will need up to 40 sensors, each requiring an unique I2C address. I could imagine to set up a chain like this:

40 pcs. of Tmag3001 are all connected to VCC and GND. The address pin of each device has a pull-up to VCC and is connected to the INT pin of the preceding TMAG3001. Only the address pin of the first TMAG3001 is connected to ground. This way, I could imagine to achieve a different address of the first sensor on power up, which will allow to address it explicitly and set a new unique address using its registers. Furthermore, I would be able to configure the first sensor to pull its INT-pin low to change the address of the second sensor. Thereby giving it a unique address for being able to repeat the seps I mentioned for the first sensor.

Now the main question: When does the TMAG3001 sample the address pin? Is it possible to change the address (using the address pin) during operation? Is there another recommended way to solve this issue?

Best regards,

Markus