Tool/software:

Hello,

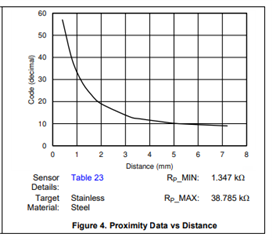

We use the LCD1001 sensor to detect the presence of metal objects on our product.

We are able to detect several types of objects of different sizes, but larger objects cause the sensor to overload.

We can't currently change our HW design to properly detect these objects (to get an RP between RPmin and RPmax).

We'd like to know how to detect that the sensor is overloaded so that we can send the alert back to our product.

We've thought of using the STATUS register (0x20) and catching the oscillator timeout events, but is this a foolproof method?

We saw in the datasheet that one of the causes of this error (oscillator timeout) is an Rp lower than RPmin. But we don't know if this is a reliable way of concluding that the sensor is overloaded.

Is this the only way to conclude that the sensor is overloaded by a large metal object?

If that's not enough, how can we be sure that a large metal object is causing the sensor to overload?

Is there more than one piece of data that can be cross-checked to obtain a reliable conlusion?

Best regards.