Other Parts Discussed in Thread: TMAG6180

Tool/software:

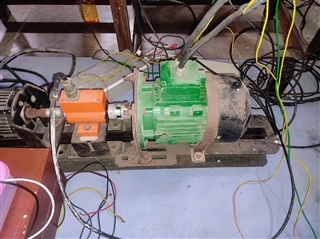

I'm developing a drive circuit for switched reluctance machine. The machine is 3500W. I have following doubts on using TMAG6180-Q1 as rotor angle sensor.

1. Can i use this sensor for a big machine like this?

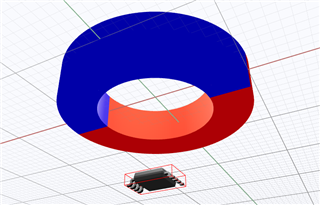

2. can you provide mounting instructions to mount magnet the shaft and placing the IC on the same axis of magnet. If

you have any pictures or application notes regarding mounting that would be of great help.

you have any pictures or application notes regarding mounting that would be of great help.

3. what type of magnet should i use on the center of the shaft?