Tool/software:

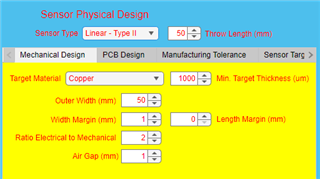

Are there any tricks to get the Sensor Designer to generate with Sensor Type "Linear - Type II" ? Everything I try just gives me some type of error beep, and the Design button stays yellow.

Alternately, a 250mm+ reference design could be helpful.