Tool/software:

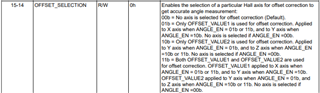

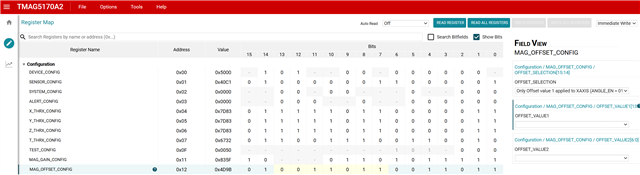

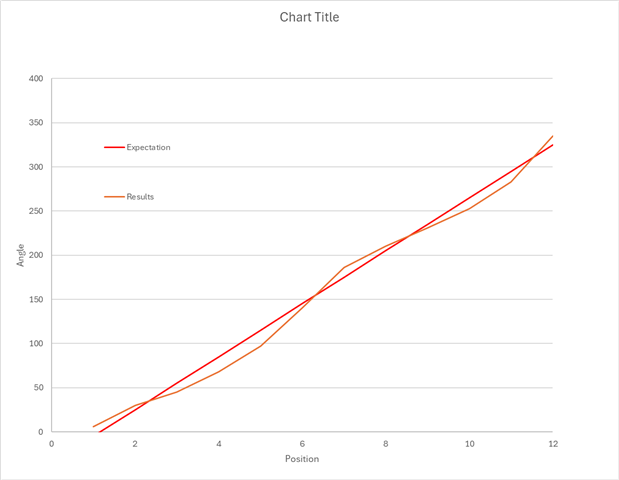

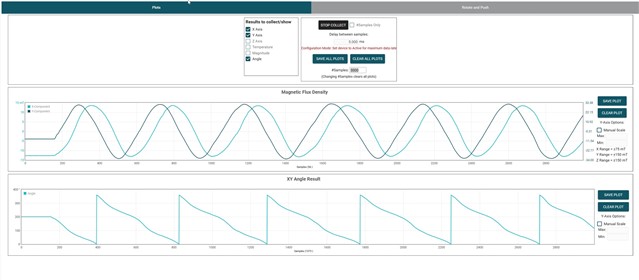

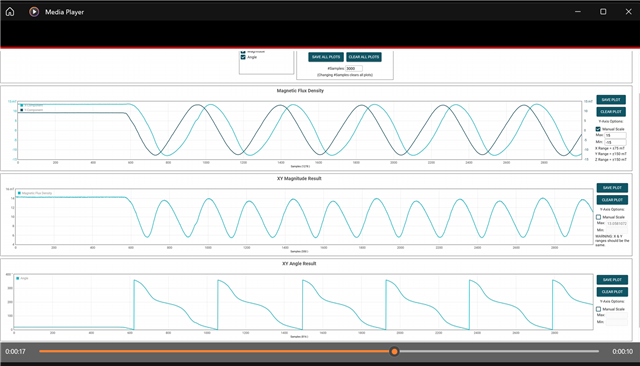

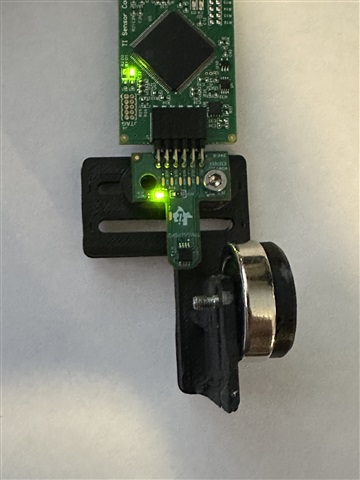

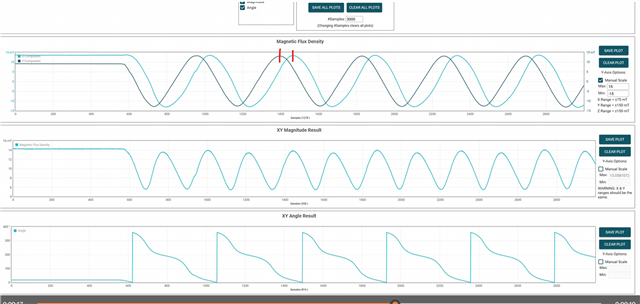

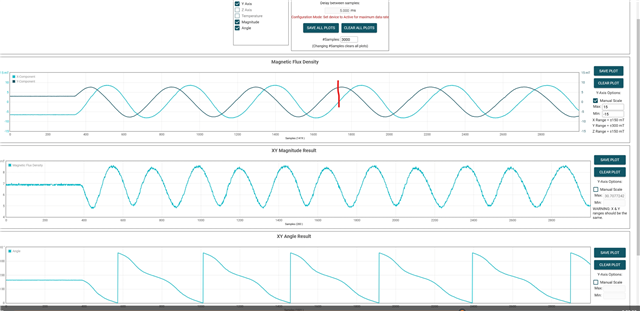

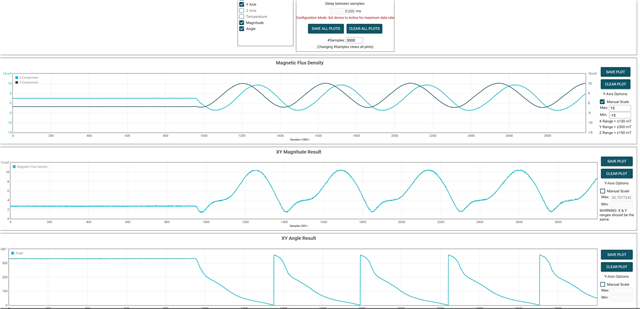

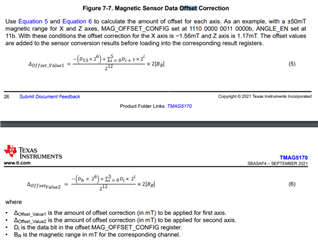

I have an off axis diametric magnet I am sensing position on. Using the Angle_En - XY I am able to get a fairly decent response, but the response is not too linear, more sinusoidal. I next began to adjust the sensitivyt of the X axis to +/- 75 and Y = 150. This helped to reduce the error. Next I adjusted the mag_gain_configs so that the XY outputs had the same magnitude, according to 8.2.2 Detailed Design Procedure. I did not see an improvemnt in my results. Is there something more I should be adjusting? Do I need to be adjusting MAG_OFFSET_CONFIG?