Tool/software:

Hello there!

In the last few days I looked through this forum in order to help us with some issues we have with the LDC. This post is about an issue we call "wrap around".

First, our setup:

We have three coils arranged in such a setup. In the middle of it a copper rod is inserted. We use this setup to measure the thickness of the rod. It works surprisingly well.

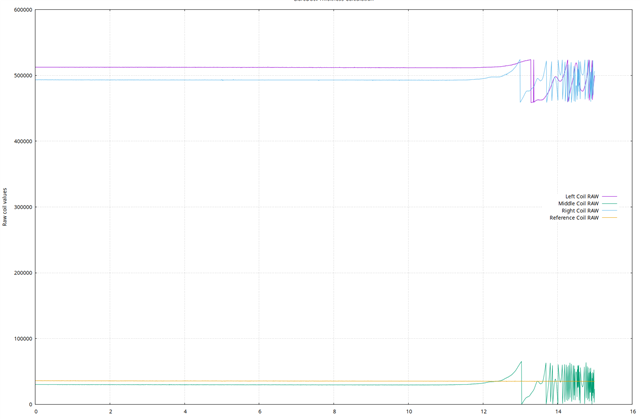

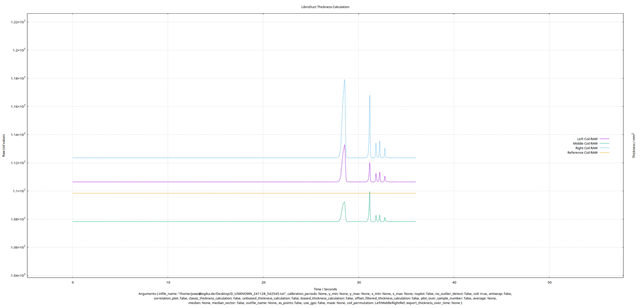

On to our issue: When the rod is cut in half (lengthwise) or placed off-center, we observe an issue that looks like an internal integer overflow or something similar happening:

This issue only seems to appear on the coil that is farthest from the copper. Interestingly, the distance between the coil and the copper in this scenario is in the same ballpark as the diameter of the coil.

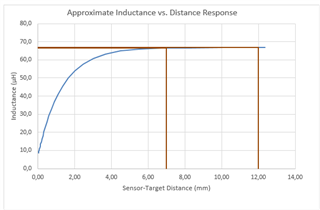

We wonder if this is something that can be resolved via config, or if this is a design error. I played a bit with your LDC Calculator Tool and came to the conclusion that the SNR is really low in this scenario because we're almost in the flat part of the curve. This might be related to the observed issue and is something we want to fix in the upcoming version. However, this is still something we'd like to understand before proceeding.

This is the tool's output when entering our worst case parameters. This might be related to the wrap around.