Tool/software:

Hello all,

I am on the process of the conceptual desing of a drive. In this drive I am planning to use TSC (top side cooled) MOSFETs. The whole package is roughtly 15mmx15mm and is a half bridge.

In previous designs, for the temperature measurement of the mosfets I have either used PT1000s or the integrated temperature sensor in the package of the transistor (mostly when I have worked with power modules).

For this design however, I wanted to do something different.

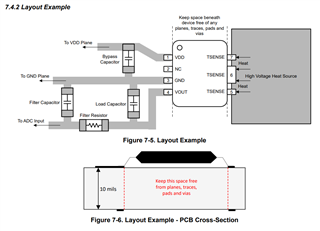

Since I am planning to have all the domains of the drive in one PCB board, and packaging size and simplicity are important, I was wondering if using a temperature sensor like ISOTMP35 and placing it close to my MOSFETs makes sense. In an application note from TI, I see that this type of sensor can also be used for GaN/SiC or Power Mosfets however, I am not sure how I would have to manage its placement with respect to this TSC MOSFET and if it is even advisable to use this sensor for such MOSFETs.

I have been trying to find application notes or documents (from TI) that touch upon this subject, but I haven't been able to find anything.

So if anyone of you has used these sensors for such applications, has documents related to it, or any advice, I would really appreacite it.

Thanks in advance,

K.K