Tool/software:

Hi!

We are using the DRV5032ZE.

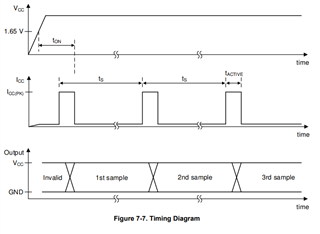

In the data sheet table, the sampling period ranges from 13.3 to 75ms and the table data applies from VCC = 1.65 to 5.5V.

Is the nominal sampling period strongly correlated to or is a function of VCC?

In our design VCC = 3.3V. (Operating temperature is 15-30C)

If the sampling period is a function of VCC, can you provide any characterization data of what the nominal sampling period at VCC = 3.3V?

Thanks and Best Regards

Jerry Molnar