Tool/software:

Hello,

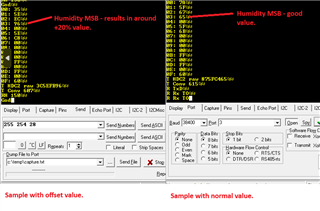

We use HDC2010 in our devices and notice constant humidity offset of around +20% on some samples.

Attached you will find prints of the sensor registers values.

Can you help as find the reason for that and solve it if possible?

Best regards,

Martin Peevski