Tool/software:

Hello,

I'm actually working on a design with the FDC2214.

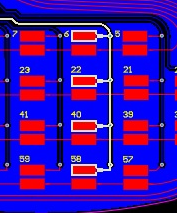

The project is a connected sole with capacitive sensors on it. The goal is to have a representation of the distribution of the weight of a foot on a sole. All the sensors are represented by a matrix of 11 lines and 8 columns. The same way as a keyboard for example.

The sole includes around 80 sensors. For each sensor 1 plate is connected to the FDC2214 using 1 of the 11 lines and the other plate is connected to ground using 1 one the 8 columns.

To control the differents lines we are using 3 FDC2214 so we can control up to 12 channels (lines). And to control the columns we are using a multiplexer to connect the selected columns to ground.

For example, selecting sensor n°32 is selecting the line 3 and columns 2. To do this we will activate the channel 3 of the FDC2214 n°1 and connect the columns 2 to ground. We will do this for each sensor to have a representation of a foot on the sole by comparing all the value measured.

We choosed to used the FDC2214 in single ended with one plate to ground to minimize the number of cables and the complexity.

I wanted to have your feedback about this project on how we can use the FDC2214. Maybe there is a better way to do this ? Or maybe you had already a similar project ?

Thanks in advance,

Alban Le Piver