Other Parts Discussed in Thread: INA186

Tool/software:

Hi Team,

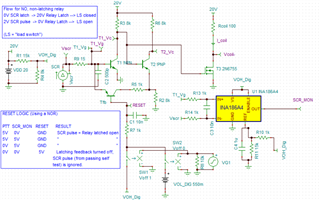

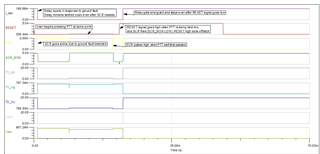

I have a question regarding Test- Reset button and solenoid operation.

1) Could you please tell me if the button used at PTT is for test, how can we do reset? If reset is done with the same pin (PTT), can you please help us understand its mechanism.

How it is different from SW_OPEN pin.

3) Can you please explain how PH and SCR_TST pin works.

4) Also, what modification is done if we use a relay in place of solenoid? Should it be Normally open (NO) or Normally closed (NC)?

(Relay would be of SPDT type, with coil voltage 24Vdc and contact voltage 120Vac.)

5) Can you please provide a flow chart if NO relay is used.

As per the datasheet (Fig 19 & 20), a single gate pulse is given during actual fault. After this single pulse, will SCR turned off?

How will a NO relay remain energized after SCR is turned off

Looking forward to hearing from you.