Tool/software:

Hi

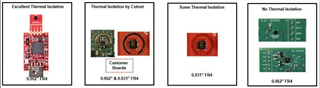

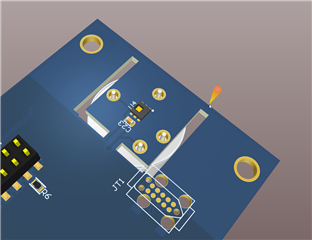

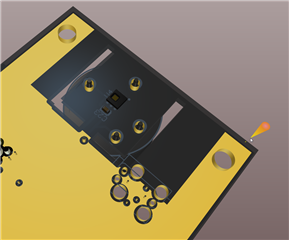

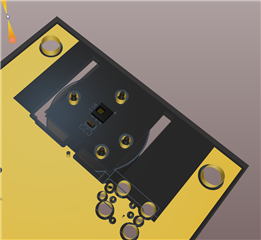

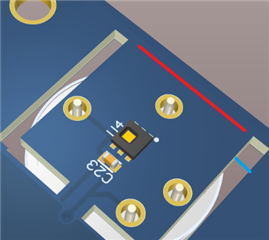

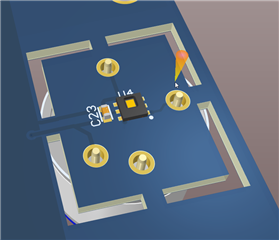

I am trying to measure the ambient temperature and humidity for example of a room, but due to the heat created on board during the charging of the battery, the temperature seems to be much higher. Is there anything that can be done on the PCB to isolate the heat transfer to the sensor? I am thinking the heat is being detected due to the connected GND plane