Other Parts Discussed in Thread: AWR2944

Tool/software:

Hi team,

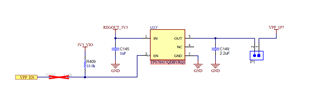

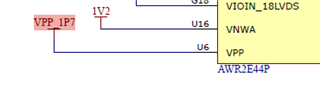

When customer check TI EVM schematic, TPS78417QDBVRQ1 using for efuse.

It doesn't matter if they don't use that part in the development stage, but I think it will be necessary during production.

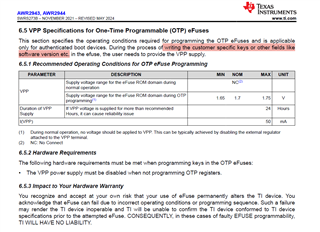

When I check the AWR2944 Datasheet, 1.7V is needed to write the key once before production, but it seems that the method is not suitable for the field board.

Can you explain how to efuse? Are you have any jig board regarding this?

Regards,

Lina