Tool/software:

Hello TI Engineers,

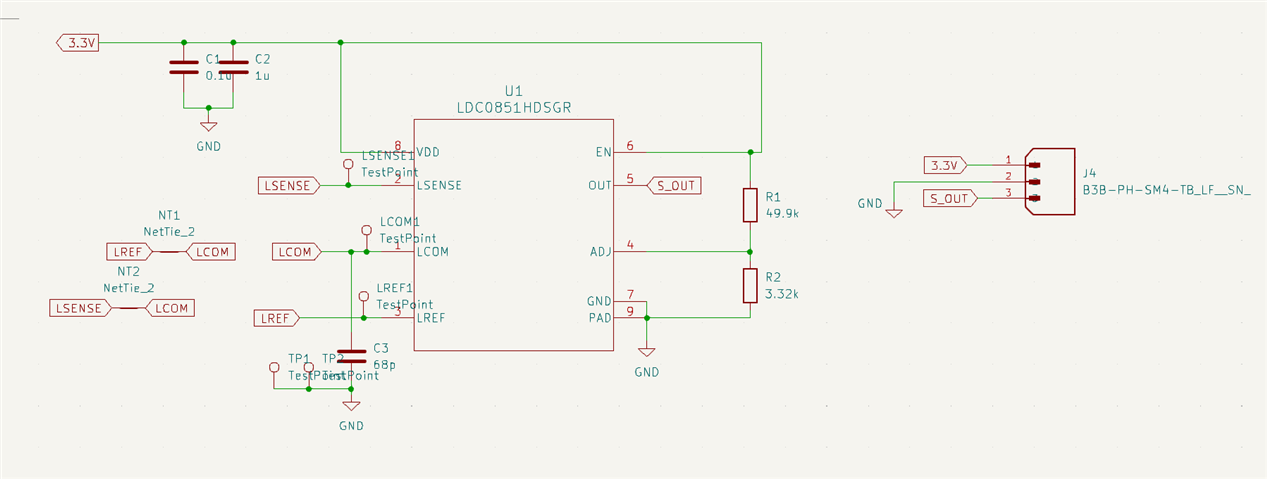

We have designed 4 inductive sensor boards with the LDC0851 sensor IC. It is designed on a 4 layer board. The first two layers are LSENSE and bottom two layers are LREF. The design was based of the LDC0851EVM.

All 4 have different outer diameter and inductance value. All 4 use the same Sensor Capacitor at a value of 68pF. The resistors going to the adjust PIN is set to trigger at the furthest distance. The values are based on the datasheet.

Below is a schematic of all 4 since they only vary with the coil trace in the layout

Below is a table of the PCB version, coil diameter and inductance. These are all designed with coil designer web bench form TI

|

PCB Version |

Inductance |

Diameter and Turns |

Coil Trace and Spacing |

|

V5 |

9.075uH |

16mm 15 Turns |

0.178mm / 0.178mm |

|

V5b |

14uH |

20mm 17 Turns |

0.203mm / 0.203mm |

|

V6 |

28.263uH |

25mm 21 Turns |

0.203mm / 0.203mm |

|

V7 |

31.04uH |

30mm 20 Turns |

0.254mm / 0.254mm |

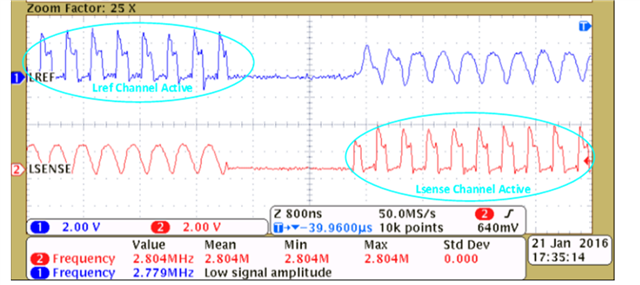

Version 5 was fully assembled by an SMT house . For the Versions 5b to V7, we ordered bare boards and hand soldered them ourselves. I do not know if the issue we are seeing is because of the hand soldering or a design issue. We did have previous issues of the sensor not actually working, but some assemblies worked right away.

The issue we are seeing is the on all Version 5b to V7 PCBA that we assembled that is functioning. Functioning means, when there is no metal, the output is 3.3V and with the presence of a metal the output drops to 0V. We built a circuit similar to the EVM where an LED turns ON then the sensor Triggers.

What we are seeing is that Versions 5B to V7 are triggering twice with V7 having the worse double trigger response.

Our test setup is that we have a metal plate that is significantly larger than largest diameter PCB design that we have.

For version 5B and 6. When we bring the metal closer it first triggers (LDC0851 output goes from 3.3V to 0V) then it un-triggers (output goes to 0V back to 3.3V) as we bring it closer, then triggers back all the way until the metal plate touches the PCB. I do not have the exact measurement of the distance but I were to express from 0 to 100 (0 is when the PCB and metal plate touches and 100 is the first time it triggers), below is the range

V5B

1. 100 to 80 - triggers

2. 80 to 60 - un-triggers

3. 60 to 0 - triggers

V6

1. 100 to 70 - triggers

2. 70 to 40 - un-triggers

3. 40 to 0 - triggers

For V7, it sometimes un-triggers twice and it un-triggers when the metal is touching the PCB.

When the metal is cover the full coil, it un-triggers but when I move the metal such that it is covering only half the coil, the sensor gets triggered.

For Version 5, all 10 PCBAs that were SMT machined only triggers once.

Can these double triggering issues be related with the hand soldering? Or is combination of increase in diameter and inductance value playing a part in this issue? Or a combination of all 3? (hand soldering, diameter and inductance value). Let me know if you need more details on the design. The measured inductance on the assembled PCBs we have tested are close to the designed value by 2-3uH.

Is there an an ideal coil fill ratio? Is there a recommended distance between edge of the PCB and the coil or distance between the coil and the rest of the circuit? Aside from the side of the coil that has the other components there are no components on the other sides of the coil similar to the EVM.

Thanks,

Deniel