Tool/software:

Hi, TI expert

Customer's products are as follows: Industrial Portable Multi gas detector

The customer wanted to apply LMP91000, but is inquiring about alternative solution.

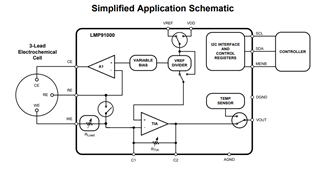

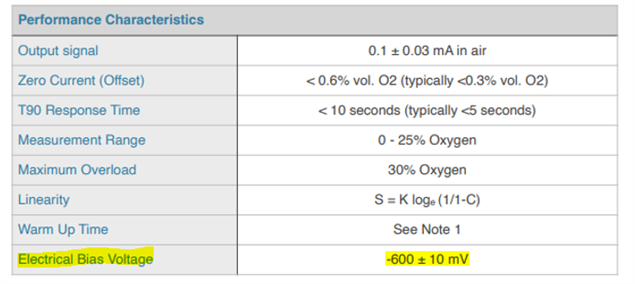

As introduced in the datasheet of LMP91000, the programmable features of LMP91000, such as adjustable bias voltage, adjustable gain resistance, and adjustable load resistance, were intended to be applied as an advantage to support multiple types of electrochemical sensors such as 3-electrode toxic gas sensors and 2-electrode galvanic cell sensors with a single design.

However, due to the issue of not being able to use the programmable component during the intrinsically safe explosion-proof certification process, it is expected to be difficult to apply the LMP91000.

It became necessary to find a solution consisting of a non-programmable component that can replace this advantageous function.

Q1) Is there a solution that can be designed to apply multiple types of electrochemical sensors in a single design without setting registers (non-programmable components)?

Please check. Thank you.