Other Parts Discussed in Thread: FDC1004,

Tool/software:

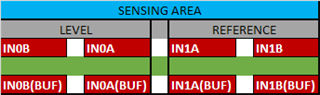

I'm currently using the FDC1004 capacitive sensor in a design, and I'm running into limitations due to the maximum sample rate of 400Hz. I'm using a custom rigid-flex sensor with active shields, very similar to the Out of Phase Liquid Level sensor example with some minor dimensional tweaks (https://www.ti.com/lit/an/snoa925/snoa925.pdf?ts=1747250607381) The data I'm getting is great, but the sample rate is a bit too slow to accomplish the customers goals. I've been looking at the FDC2212 and I find it interesting because of the higher sample rate, but it doesn't have some of the integrated features - specifically the active shield. Is it possible to use the device in a similar fashion to the FDC1004 OoP level sensor using external op amps to derive the shields? Is a significantly higher sample rate possible while still maintaining sub pF resolution in the ~0-100pF range? The sensed material is non-conductive.

Thanks!