Other Parts Discussed in Thread: HDC3020

Tool/software:

Team,

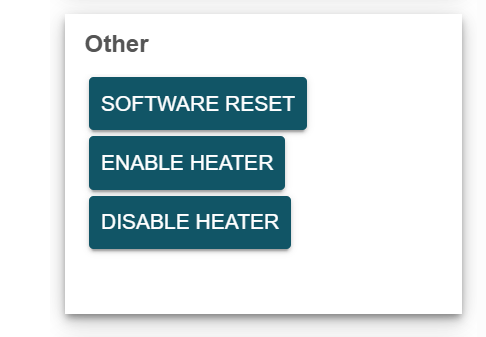

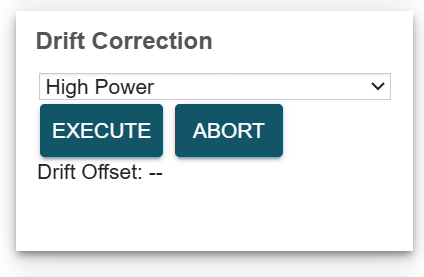

Customer enabled heater with command 0x306D. Read status through 0xF32D command and return 0x2000 bit 13=1 mean heater is enabled. The heater is configured as 0x3FFF, full power.

But after 5s~10s running, the temperature is still at 26C (This temperature is reported by both HDC3020 and other external temperature sensor).

Why doesn't the heater seems take effect? This doesn't happen only for one board. This happen for all the boards at customer side.

Thanks