Tool/software:

Hi TI experts,

While developing a new application for our custom board, we observed inaccurate temperature sensor readings.

Specifically, the temperature values retrieved via rl_fecssTempMeasTrig sporadically jump from approximately 40°C to around 130°C within a 60ms window – despite stable ambient conditions.

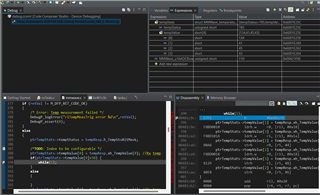

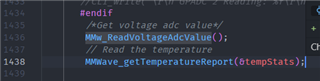

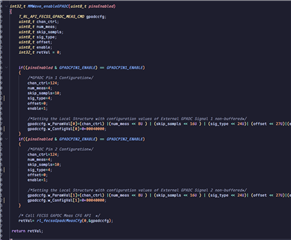

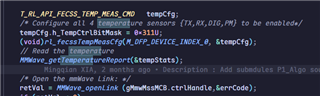

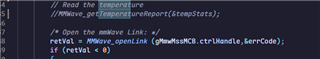

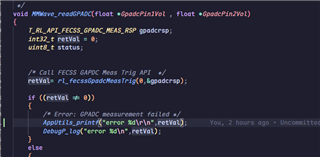

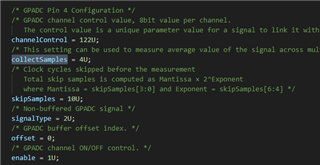

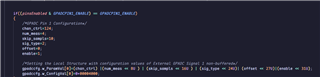

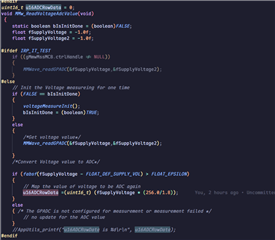

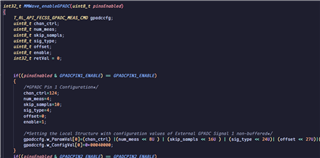

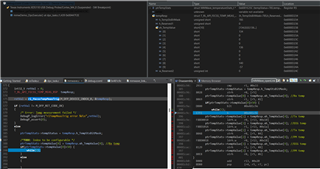

The relevant code section and variable states are captured in the attached snapshot.

After we re-start the sensor, the temperature change to normal.

Have you encountered similar issues? Could you provide recommendations for in-depth debugging?