Tool/software:

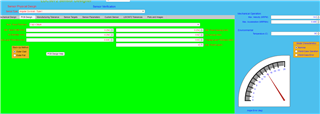

I have several questions regarding the use of the LDC5072 tool:

-

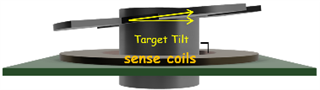

Under the "Sensor Type" section, there are multiple options like Angular Coaxial Type I, Angular Off-Axis, and others. Could someone please help me understand what these configurations mean and how to select the right one?

-

My sensor is placed at the end of the shaft. I would like to know if this positioning affects the performance or if any special considerations are needed.

-

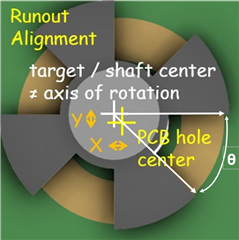

I am currently seeing an angle error of around 4 degrees, but ideally, I want this error to be as low as possible. What steps can I take to reduce the angle error?

-

I am using the Outer Foil method in the stack-up. Is this appropriate, or should I consider any alternatives?

-

How do maximum acceleration and maximum speed values impact the tool’s performance or output? Are there recommended limits?

-

What are the standard values one should enter for manufacturing tolerances?

-

Regarding the optimizer targets, I haven’t modified any settings. Is it okay to leave them at their default values?

-

Lastly, for the LDC5072-specific settings, do I need to change any default parameters, or are the existing values suitable for general use?

Your guidance would be highly appreciated.