Tool/software:

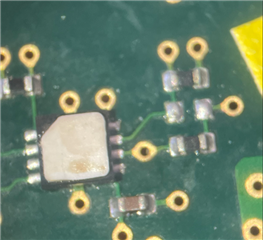

We noticed a browned appearance on a component that we assembled by hand (it's our prototype process, temperature is less well-controlled).

We therefore believe that the component is damaged and we are wondering about the rework conditions.

According to the datasheet, here are the conditions:

8.4.3.3 Rework

TI recommends to limit the HDC302x to a single IR reflow with no rework, but a second reflow can be possible if

the following guidelines are met:

• The exposed polymer (humidity sensor) is kept clean and undamaged.

• No-clean solder paste is used and the process is not exposed to any liquids, such as water or solvents.

• The peak soldering temperature does not exceed 260°C.

Can please precise point below?

- No rework ==> Does this mean that all soldering rework is prohibited and therefore component replacement is necessary? Or does the entire board have to be scrapped ?

- Can you also specify if there are specific hand soldering instructions? Except for the indication not to exceed 260°C