Other Parts Discussed in Thread: IWRL6432, , IWR6843AOP, IWR1843AOP

Tool/software:

Hi expert,

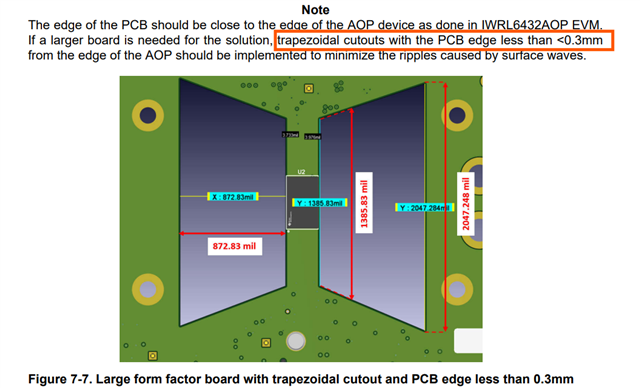

The customer has previously evaluated the IWRL6432 and intended to use the AOP version.

However, they have now found that while the IWRL6432AOP is identical to the IWRL6432 in terms of principle and packaging, an additional design requirement has been introduced, which will significantly increase the difficulty of routing.

Since this requirement was not included in the original reference design, they would like to know the reason for adding it. In addition, as no clearance is reserved on the official website's development board, they also want to confirm whether this new requirement is put forward due to related issues.

Could you help answer their question?

Best regards,

Winnie