I am developing a non contact flowmeter device using 630nm illumination of a target from an LED through

an optical fibre. We use approximately 250mw optical power to heat the target, and the eventual system will

use modulated LED intensity to induce a constant temperature increase on the target. The optical power

required will correlate with flow.

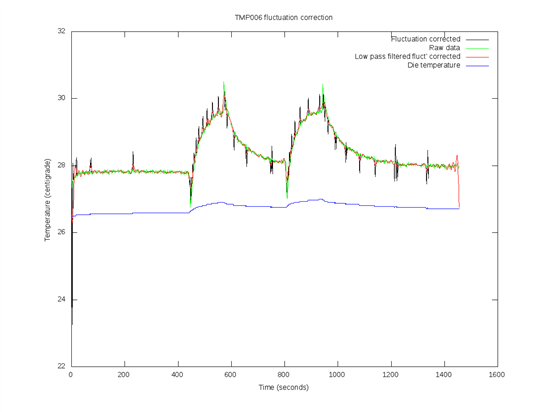

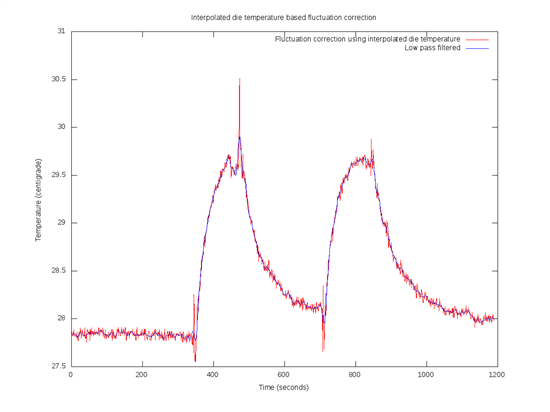

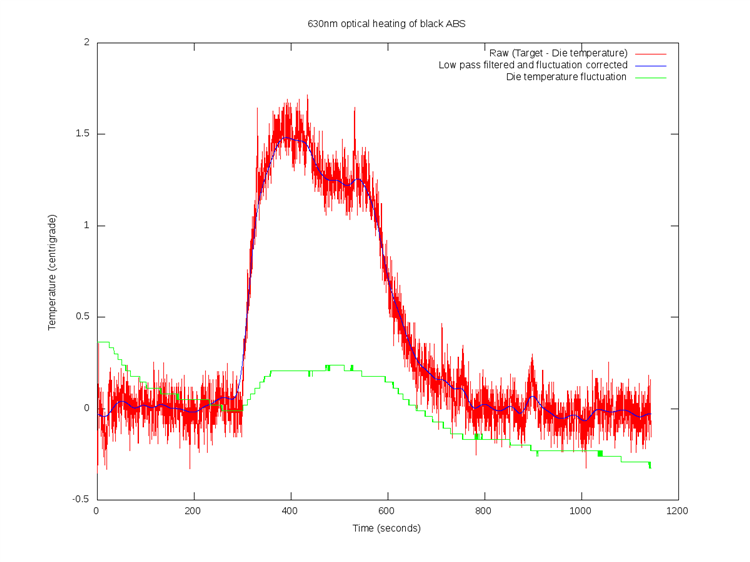

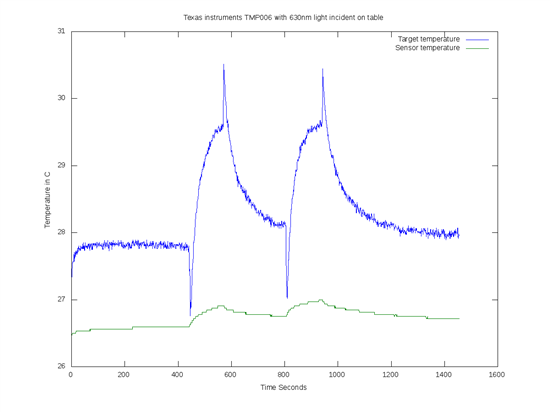

During basic testing with a TMP006 evaluation board we have noticed spikes on the output each time the

illumination is turned on/off. We suspect this is due to photovoltaic effects from the illumination light reflecting

between the IC and the PCB and striking the "bottom" side of the IC. This only seems to occur when the

illumination intensity is rapidly changed - e.g. a 0 to100mw slew over 10 seconds or similar with our setup

(approximately 10% of input light is reflecting and hitting the sensor).

Could anyone advise on the possible causes of this effect, and if the photovoltaic hypothesis is credible.

What steps could we take to mitigate the spiking apart from reducing the optical power slew rate.