Tool/software:

Hello,

Now we have a new design based in OPT4048 and STM32F103C8T6 and which will be used on the applicatiop of LED color and lux analyze.

but we found that the mantessa_1 raw ADC value of our design is lower than your dev board OPT4048DTSEVM in the testing of a same green LED,

and as you know the lower mantessa_1 value will get a lower lux value.

the detailes of our design: STM32 through I2C to control 4x OPT4048, supply voltage of OPT4048 is 3v3, and the pull up resistor of I2C and INT is 4K7;

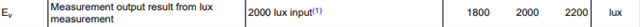

test results of our design and OPT4048DTSEVM(average value of 50 samples)

convert time =100ms; Delta= (our board-Dev board) / Dev board

| CIE x | CIE y | lux | CCT | |

| Dev board | 0.26456 | 0.65734 | 457.769 | 6573.16 |

| Our board | 0.26728 | 0.65365 | 402.38 | 6536.15 |

| Delta | 1.03% | -0.56% | -12.10% | -0.56% |

Questions:

1, What will impact the OPT4048 ADC reading and what possible reasons will cause the lower output of lux;

2, Do you have any suggestions on our design,especially for the design of applications using multiple color sensors?

3, Did OPT4048DTSEVM undergo special calibration in your factory?