Hi,

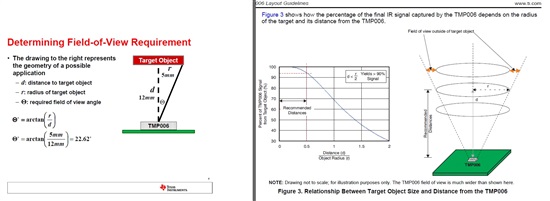

I'm working on a project , and we are trying to measure (to scan ) a PCB temperature . Eg. we have 10x10 mm board and a like to have 100 point's of temp. measure(1x1 mm).

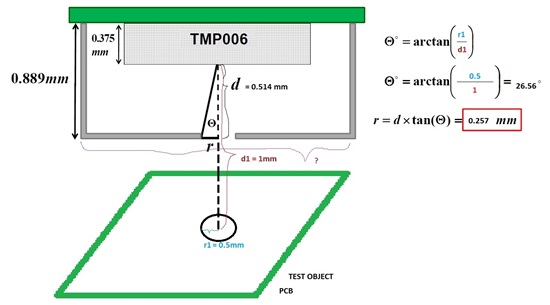

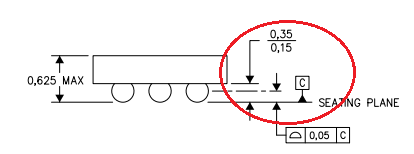

The TMP006EMV should be 1 to 5 mm away from the target object. I calculated the cover size and attached my calculation for 1mm distance.

1) Can you pleas check the calculation if it's correct?

2) What is the size of cover marked with "?" on the picture?

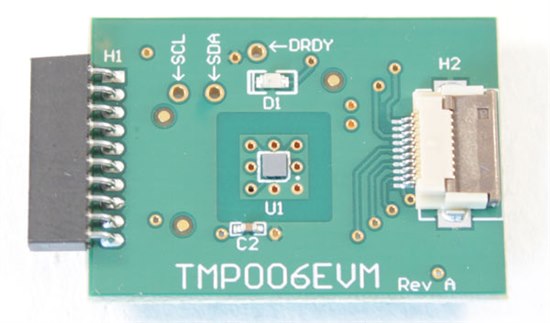

3) Currently we are using TMP006EMV but in the future we are going to try connect the module on our board without the USB-DIG and I would to know what is the output data of TMP006 on the I2C, It's the object temperature or voltage and what code do I need to use to convert the voltage from I2C to object temperature , do I need to use the TRANSIENT CORRECTION and how?

Regards,