Please let me know three below about the directions for TMP006.

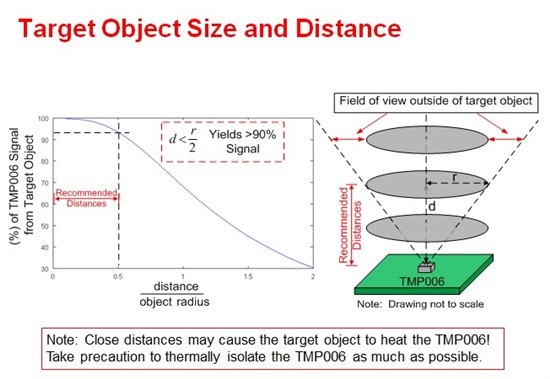

- Does measurement accuracy get worse in distance?

Are there related data and distance permitted then?

- How long [ maximum ] is the measurement temperature range of IR?

(It was writing to the register setup of a data sheet to 150 ℃)

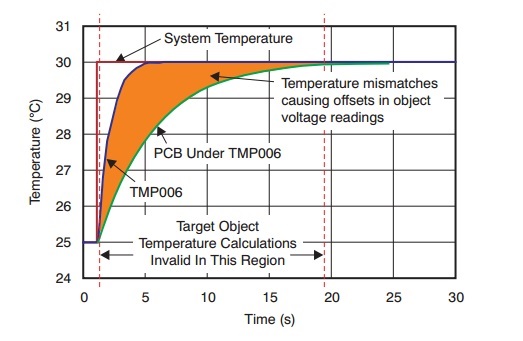

- Although cared about the measurement accuracy of IR sensor worsening by the rise of ambient air temperature (Local),

Does Fig. 3 of URL show the graph after the calibration was carried out below?

And if there is the method of maintaining the measurement accuracy of IR sensor, please let me know.

http://www.tij.co.jp/jp/lit/ug/sbou108/sbou108.pdf

Thank you for your consideration.