Hi there,

I'm looking to build a general purpose open source stepper motor digital encoder from the LDC1000 for a Kickstarter project. Steppers typically have 200 steps/rev, however many people run steppers at up to 16x micro-stepping, giving 3200 steps/rev. I'd like to sense these steps to ensure the stepper motor moved correctly.

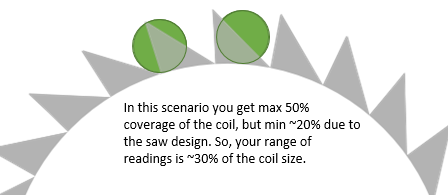

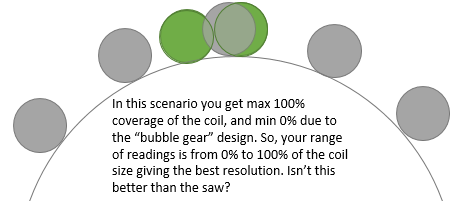

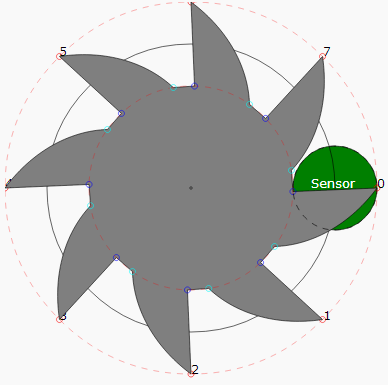

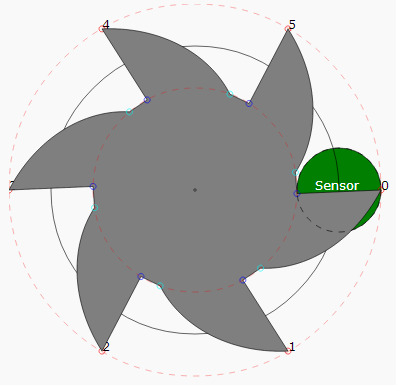

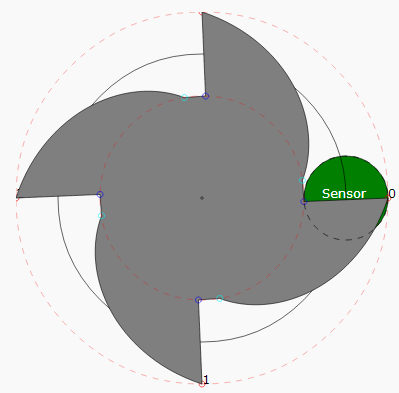

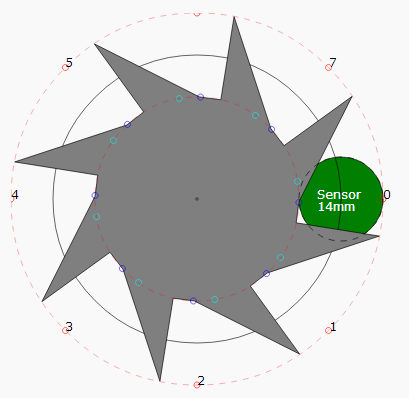

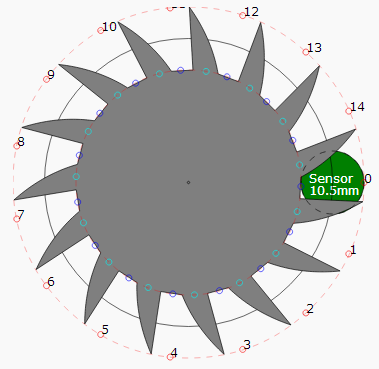

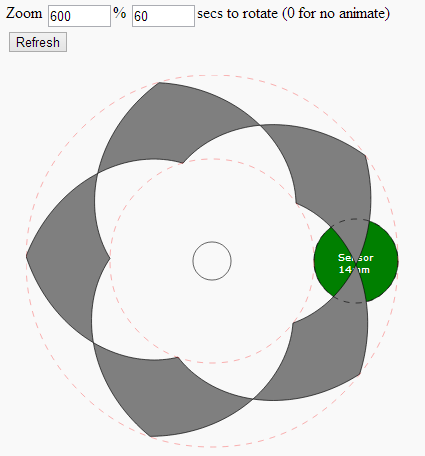

The thought is to go with a gear counting style application or perhaps the swirl measurement with 2 LDCs. I'd rather keep cost down and do gear counting so I only need one LDC. I can print a conductive ink gear with high resolution to create 3200 "gears" at the outside diameter of a plastic circle that would mount to the stepper motor axis. The diameter of the printed conductive ink circle would be at it's widest 42mm. I could perhaps make the "gears" be about 1mm in length and put them as far out on the circle as possible, i.e. at 41mm diameter stretching out to the 42mm in diameter. The circumference of that circle is roughly 132mm so the "gears" would have to be 20 microns of conductive ink, 20 microns of no ink, etc. Is it feasible to detect gears this small? The datasheet and marketing materials refer to detecting sub-micron resolution so it seems I'm well above that at 20 microns.

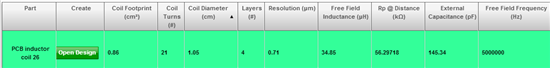

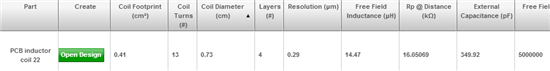

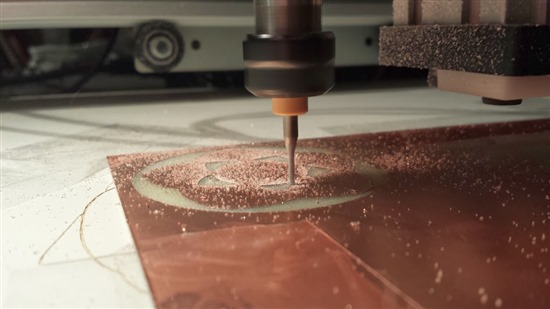

A further question is, what size coil on a PCB would be needed to detect the 20 micron wide gears and their movement? From reading the datasheet and forum it seems like a coil the size of the circle would be needed, but if you are counting gears is it a different formula? I could do a coil with a 42mm diameter if needed but it would make for a large final package. Or, could I do a much smaller coil, say a 10mm one, since I'm detecting gears with motion parallel to the coil rather than detecting distance? Would a 1 layer PCB coil be good enough as well?

Thanks,

John