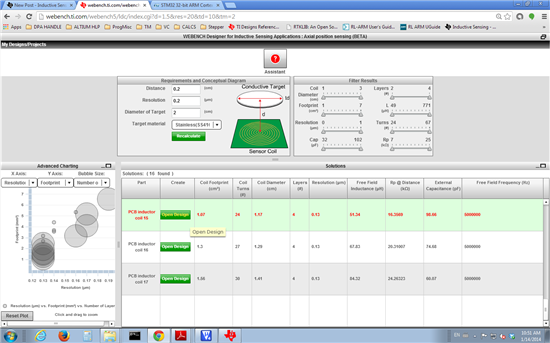

I have made some trial with the EVM and custom PCB to evaluate the LDC1000 for a possible use in proximity

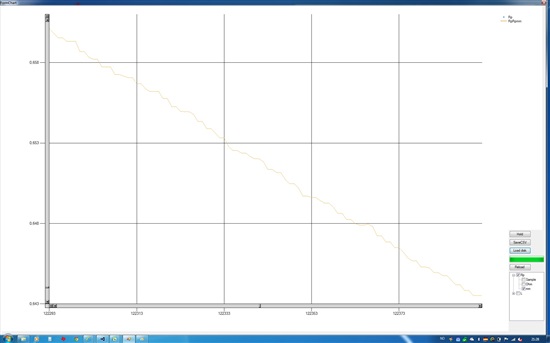

sensig application. I need to measure the distance between the pcb coil and a metal target with 1µm

(or better) resolution. The maximum distance is about 0.2cm. The design parameters for my PCB coil are:

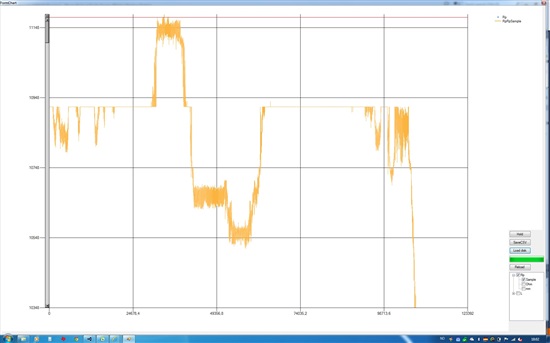

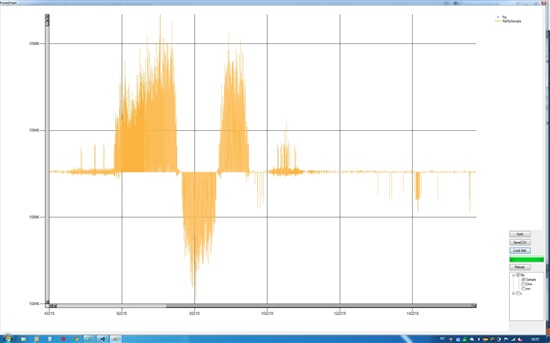

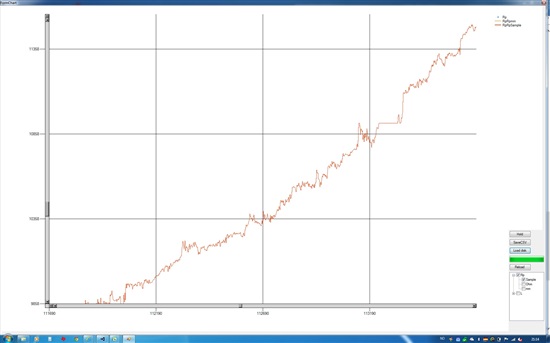

So far i have managed to get about 1V peak-to-peak at the CFB, set up RP_min and RP_max so that my proximity

readings are between 3000(max. distance) and 20000(min. distance). My headache at the moment is that when

the proximity reading reach the value 10922 it stay at that value for the next 10-15µm then jump

to 11000 and above. I am observing similar behavior with the EVM - when the proximity reading is 10922 the

device is "frozen" for the next 30µm. I guess i am doing something wrong here, but I'm running out of ideas

what to do next :)