Hi,

I'm using a custom coil to test some tiny movement. The coil is designed from the Webench:

http://webench.ti.com/webench5/ldc/index.cgi?c=20.67&l=94.53&nl=2&nt=52&f=3600000&cres=14.25&cd=2.29&d=0.8&res=20&td=1&tm=0#

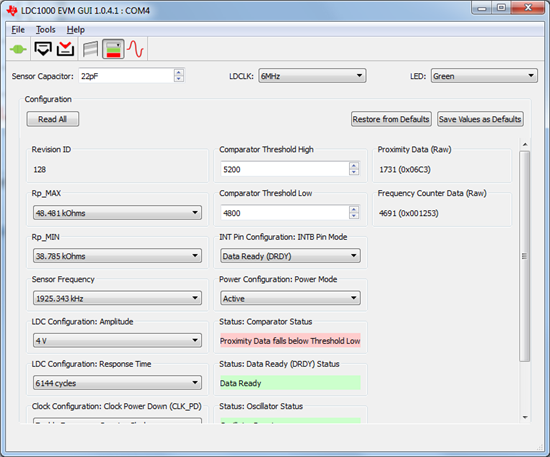

The parallel capacitor is 22pF and I change the GUI settings as following. The resonance frequency is 30.1MHz. I didn't change the filter capacitor, is that OK?

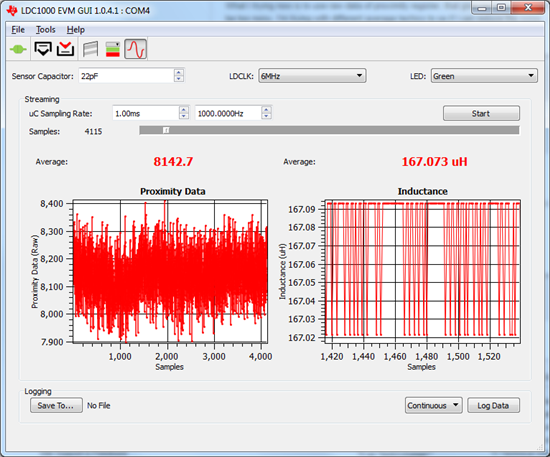

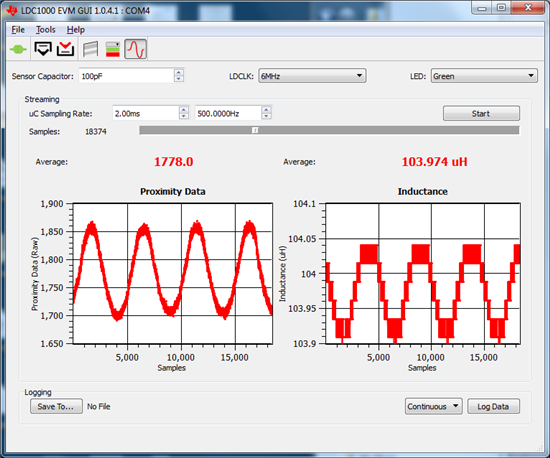

And this is the output when a small target is placed near the coil but doesn't move. Is the noise too large? How can I do to achieve a smaller noise?

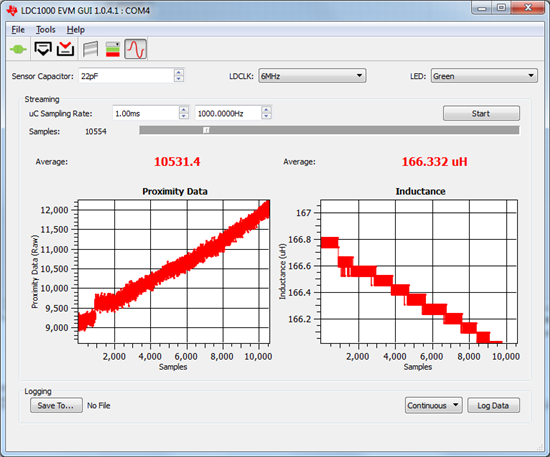

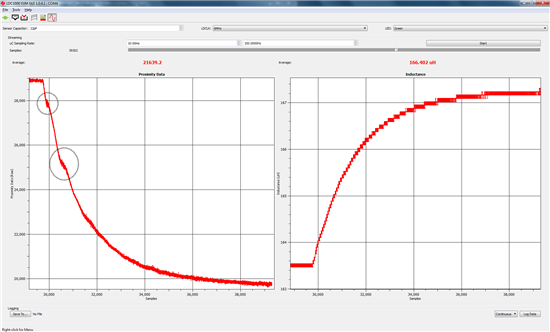

This is the reading when the target moving close to the coil in a constant speed (1000Hz step signal). Seems the resolution of the inductance reading is too low. Is there anything I forgot about the inductance setting?

Thanks,

Jiaqi