Hi,

My customer want to detect pistons of cylinders by LDC1000.

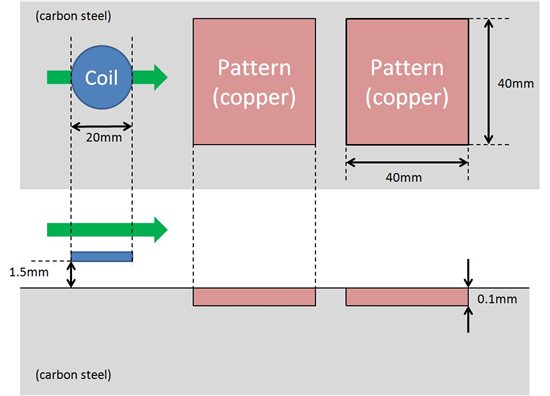

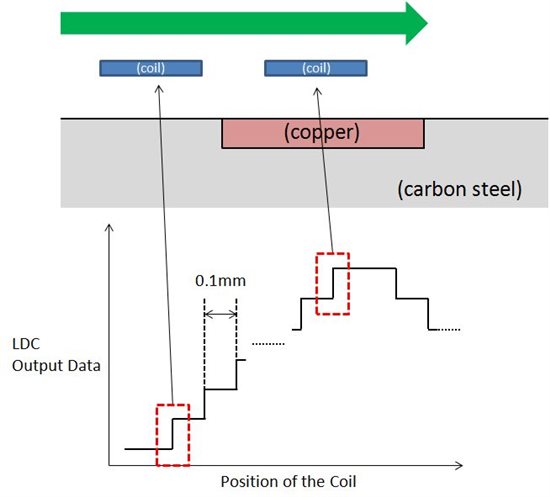

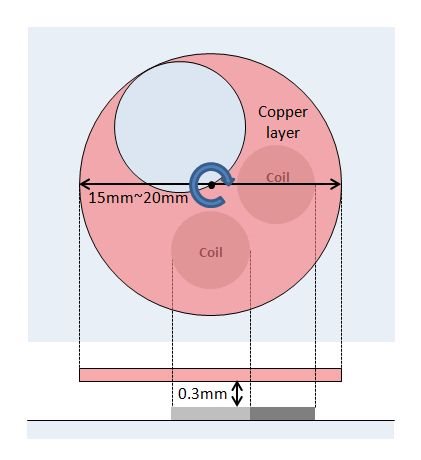

In concretely, the pattern of cylinders is detected by the sensor of coils.

I attach the figure of the condition.

The detecting point is from beginning lap of coil and pattern to completing lap.

Please let me know lack of information.

Thanks,

Kuramochi