Hello

I'm using the LDC1000 for metal composition measurement therefore a stable measurement of Rp is required. My LC-tank oscillates at around 3,6MHz (C=22pF, L=35uH).

With the standard hardware of the LDC1000 Evaluation Module (Filter Capacitor=20pF) I can't achieve the required accuracy of Rp(the measured value changes in a range of +-30).

Some things I tried:

1. Filter Capacitor=20pF(stock), air-coil

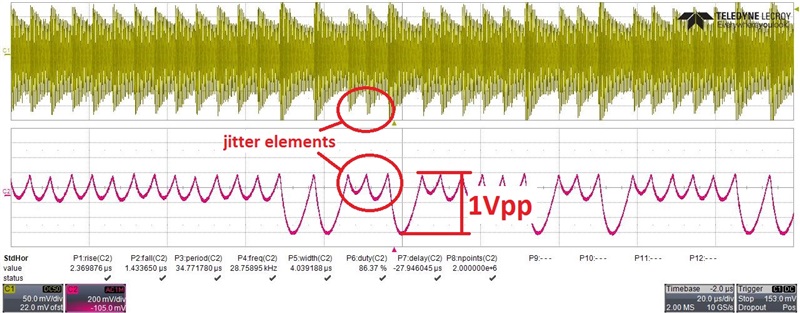

CH1: current in the LC-tank

CH2: voltage on the CFB-Pin

As you can see the measured voltage on CFB-pin is not steady. The Rp-value is not steady either(+-30). I tried to vary the values of Rpmax and Rpmin but it didn't help. The peak-peak-voltage is higher than the desired 1V so I tried another value for the Filter Capacitor.

2. Filter Capacitor=33pF, air-coil

Now I’m closer to the desired 1Vpp at CFB-pin but this time it looks even worse. The Rp-value is very unstable (+-50).

3. No Filter Capacitor, air-coil

What I tried next is to remove the Filter Capacitor at all.

Now the voltage on the CFB-Pin is clipping(5Vpp). This time the Rp value is very stable(+-1).

It seems that removing the filter capacitor can lead to a smaller tolerance of Rp.

One problem: The small tolerance of +-1 is not true for all of my metal targets, but it’s not that bad.

In your datasheet you say that the voltage on CFB-pin should not exceed 1Vpp but my impression is that it gets better if the voltage is clipping at 5Vpp. Did I overlook any difficulties or is there a better way to stabilize Rp measurement? Could you please give me deeper info on the LDC internals so I can understand the purpose of the filter capacitor?