Hello,

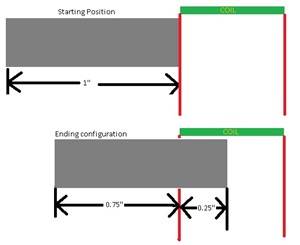

I am attempting to design a coil to measure changes in linear position. In order to do this I am going to position the rack (part of a rack and pinon system on a EM actuator) approximately 1mm away from the sensor coil and move the rack perpendicular to the coil such that increasingly larger portions of the rack move under the coil as shown below:

Will this setup diminish the accuracy in any way? I understand the measurement will be non-linear with this type of configuration but that is easily adjusted for in SW. I will be using a coil with the following parameters:

capacitance: 15pf

Free field freq. (Hz): 5M

Number of turns: 27

Number of layers: 4

Coil diameter: 1.29 cm

Coil trace width: 4 mil

coil trace spacing: 4 mil

coil trace thickness: 1.5 mil

Coil trace conductivity: 58 MS/m

These values are based on using WebBench with the following inputs:

distance: 0.1cm

resolution: 0.2um

diameter of target 1.2cm

Using these parameters I get a skin depth of 0.03 mm is that correct? If so does that mean that the coil can only sense 3xskin depth into any particular metal? What is the coils maximum sensing distance? (i.e. if I put a piece of conductive metal 3mm away from the coil would the sensor see it? How much of an effect would that have on the reading?)

Is this coil design optimum for the type of application that I am using it for? If the above application is trying to sense the rack but there is other metal on the side reverse of the rack that we don't want to sense is there a way to design the coil to not sense that metal? Would it be better to shield the coil from the other metal using some ferrite material?

Any help you can provide would be greatly appreciated.

Thank you,

Kyle